Dynamix agitators' cookie consent authorization

This website uses cookies to ensure you get the best experience on our website

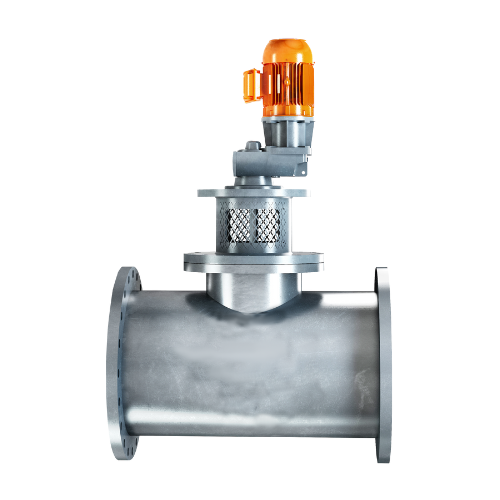

This inline mixer design allows for the addition of chemical additives directly into the pipeline flow of your process.

This design offers operators great value with increased process control vs. Static Mixers, and limited floor space as it does not require a tank.

Static mixers require a fixed head pressure for a desired mixing level. The Inline Dynamic mixer does not. Mixing is guaranteed independent of the inline flow. This allows operators to run their processes without severe flow restrictions.

Configurations can range from speeds of 292 to 1,800 RPM and flow rates from 200 to 50,000 GPM, providing cost-effective and space-saving mixer installation for your specific process conditions.

Dynamic inline mixers can be optimally configured for flash mixing and pH adjustment processes where space and project cost are major factors in mixer design.

Configurations can range from speeds of 292 to 1,800 RPM and flow from 200 to 50,000 GPM, providing cost-effective and space-saving mixer installation for your specific process conditions.

The following options are available with your Dynamix Mixer. Just work with your application engineer to select the best configuration for your tank and process.

Dynamix inline mixers are ideal for adding additives to flash mixing and coagulation processes, and pH control processes in the wastewater treatment industry, chemical treatment industry, and oil and gas sector.

The Inline installation provides mixing as part of the process flow, mitigating the capital cost of purchasing an additional mixing tank and saving the valuable space it would have taken in your facility.

Static Mixers require a specific flow or head to work. This fixes the flow rate of the process. Inline mixers work independently of the flow rate so that you can run your process at whatever rate you need.

Inline mixers are available in direct and gear configurations to suit individual process requirements and customer needs. A service factor of 1.5 allows for reliability and peace of mind due to the quality of materials and custom configuration.

The Dynamix dynamic inline mixer works with flow rates of 200 to 50,000 GPM. It can be configured from 1 to 40 hp, with speeds of 292 to 1,800 RPM. Most mixers feature either multiple-pitched blade or radial impeller combinations. The heavy-duty custom flange mount comes standard.

Don’t like filling out forms? No problem, send us an email directly info@dynamixinc.com

This website uses cookies to ensure you get the best experience on our website