Dynamix agitators' cookie consent authorization

This website uses cookies to ensure you get the best experience on our website

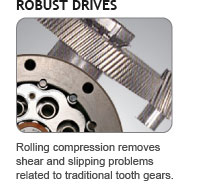

When buying a DMX portable tank mixer you are investing in torque to mix your application and the construction to ensure industry-leading life cycles. For this reason, we offer one of the widest ranges of gear reduction; (5:1 – 21:1) or (350 – 83rpm) in order to ensure we meet your needs. In addition for heavy applications, we offer our heavy-duty, portable tank mixer in the DMX mixer models. Most noteworthy, these mixers can handle shock loads that are greater than 500% of their rating. This is the reason the industry selects Dynamix when process downtime is costly, or when a process just can’t fail.

When buying a portable tank mixer, you are investing in torque and the construction to handle this torque. Due to this, we offer one of the widest ranges of gear reduction. (5:1 – 21:1) (350 – 83rpm) with our portable tank mixer line. For heavy applications, we offer our heavy-duty, portable DMX Mixer models. Consequently, these mixers can handle shock loads that are greater than 500% of their rating. Even more, this is the reason the industry selects Dynamix when process downtime is costly, or when a process just can’t fail.

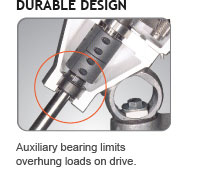

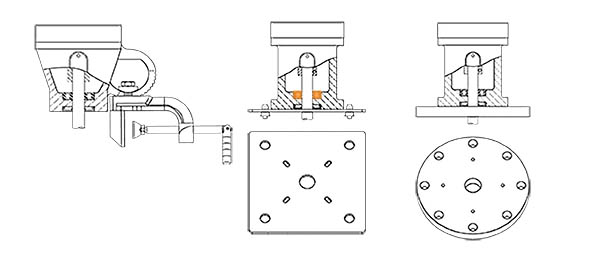

A Portable tank mixer needs to be designed for more than just their application. In addition, auxiliary bearings are the difference between an economy portable mixer and a portable mixer designed for long-term use. Do not let your mixer supplier rely on the bearings in the motor. Dynamix uses auxiliary bearings in its DMX portable tank mixers in order to isolate loads from the motor. This allows the motor to run efficiently and without damage.

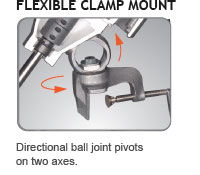

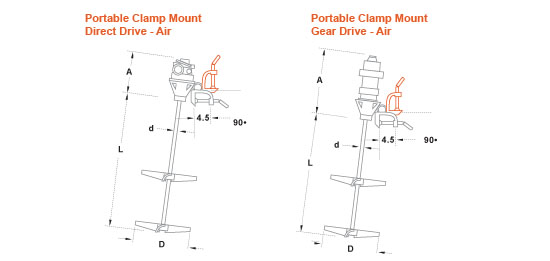

This unique ball joint configuration enables the portable tank mixer to rotate through the vertical and horizontal axes. This flexibility enables it to be used on different tanks and applications to address varying flow patterns and dead spots.

DMX 5000 SERIES

Robust portable mixer with medium and heavy-duty construction (300 to 3,000 gallons)

![]() MOTORS HP RANGE – 1/2 TO 2 HP

MOTORS HP RANGE – 1/2 TO 2 HP

custom Design it with us & optimize your mixer for your application – Get our process guarantee

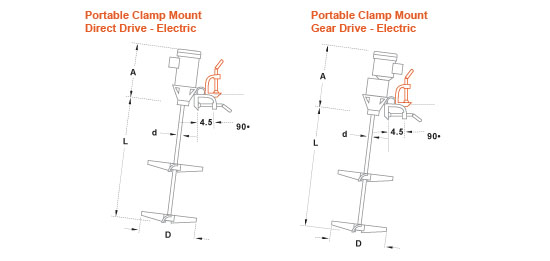

The standard clamp mount design for mixing in both open-head drums. The clamp mount is angle mounted to allow for larger diameter collapsible impellers.

Impeller selection is the starting point of any portable tank mixer configuration. Likewise, starting with the right impeller means your portable mixer will work in balance and provide quality mixing. Above all, issues such as uniformity, area of influence, shear, solid suspension, and many others are addressed by the impeller selection.

review customizable portable tank mixers model selection

Work with our applications engineers to find a customized mixer solution

Don’t like filling out forms? No problem, send us an email directly info@dynamixinc.com

This website uses cookies to ensure you get the best experience on our website