Dynamix agitators' cookie consent authorization

This website uses cookies to ensure you get the best experience on our website

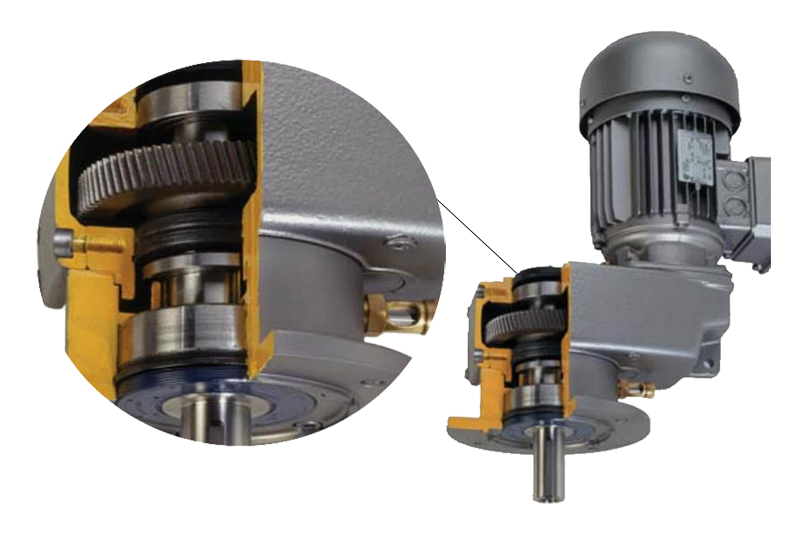

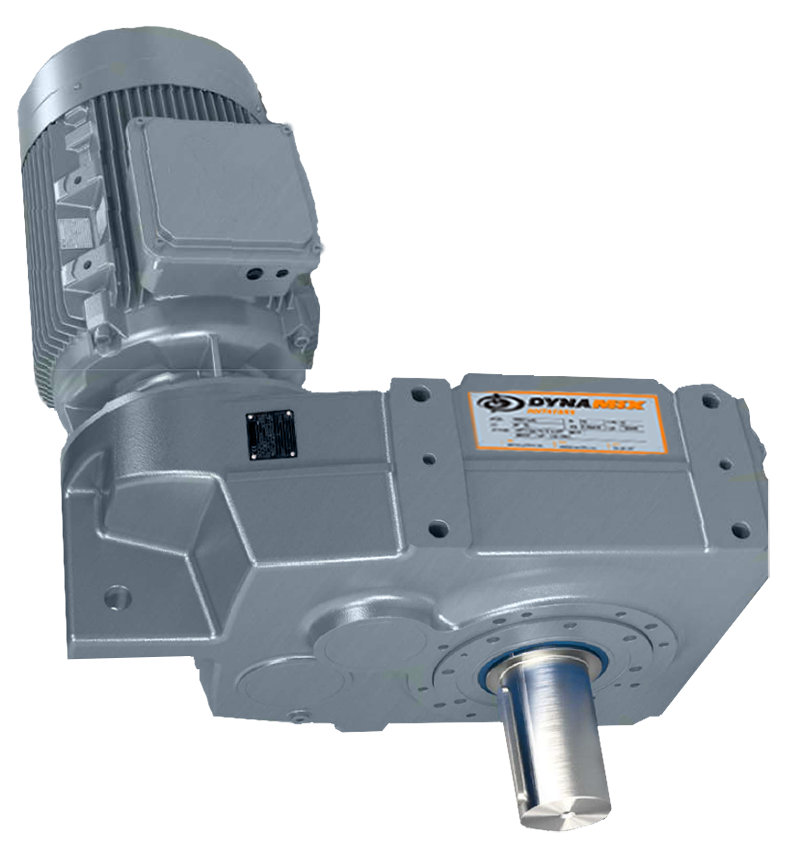

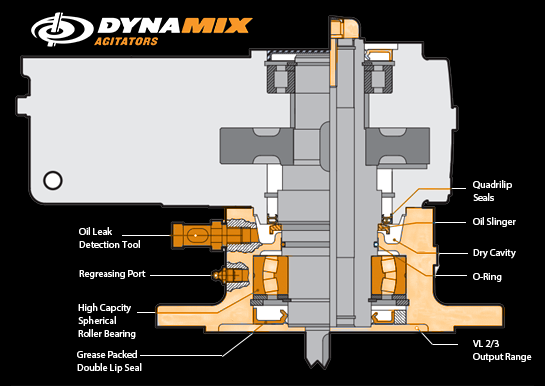

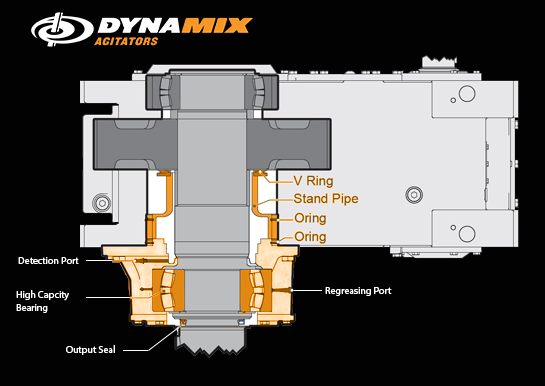

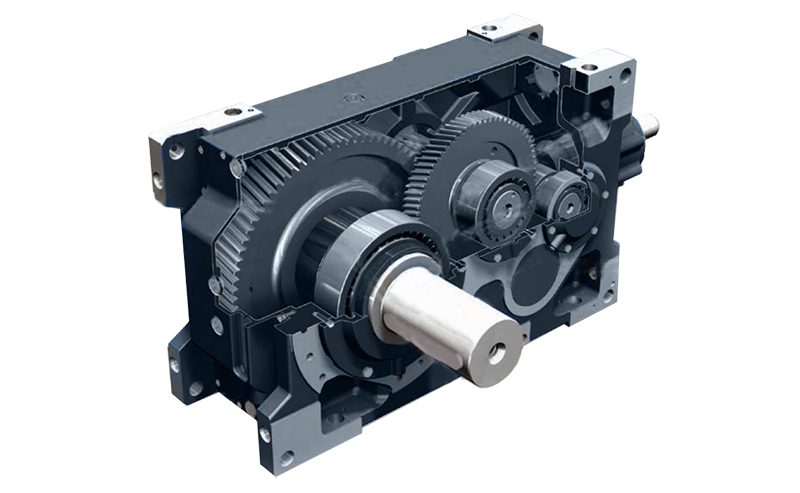

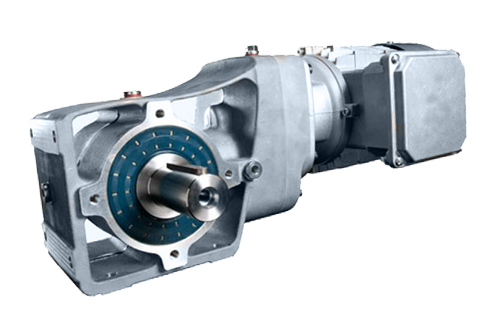

Durable gearboxes are critical to the operation and reliability of our agitator mixer designs. Our drives are built on a one-piece case to ensure a rigid shaft and precise torque performance. Cases are machined in a single operation, ensuring the long life and low maintenance of the sealing and bearings. Available in both parallel helical and bevel helical gear configurations, our team can select and configure a to suit your needs.

Our NMX industrial agitator mixer is developed for heavy-duty industry applications. In fact, the NMX Series mixer is our most robust and configurable mixer line. While the efficiency of this industrial mixer is extremely high, it is the engineering and customization that makes this mixer line successful. Learn about our industrial mixers’ key features and options (e.g., the materials used, spread bearings, design, etc.), or click the “request a quote” button below for info on our prices for these heavy-duty mixers.

Standard motor options include:

Contact Dynamix for specific certification details on each product component – available upon request, please contact us.

Dynamix uses both solid and hollow shaft designs for the NMX Series. Technically challenging and substantially more rigid, hollow shaft designs are used to optimize the performance of our industrial mixer. This design capability allows for a shaft diameter optimization that increases critical speeds, which means longer, more stable shafts.

Shaft design is one of the most technical parts of the industrial agitator mixer design. In order to optimize our mixer, we can select from 3 or 4 standard bearing spreads that utilize heavy-duty tapered roller bearings to handle high overhung thrust loads, which results in a longer service life. With the proper shaft design, steady bearings, and bump rings can be avoided. These are often used when the shaft design is not controlled or understood properly. From this, we can optimize the overhung load (OHL) and critical speeds.

Key design elements of NMX industrial mixers:

Our innovation in split-hub design enables superior performance in larger applications and makes the industrial mixers easy to install and remove.

Our innovation in split-hub design enables superior performance in larger applications and ease of installation and removal.

Full line of impeller options: pitch, radial, and our unique Dynaflow high-efficiency impeller.

The NMX’s popularity is based on how its configurations are managed by the application engineering team. Our modular design approach provides you with the ability to optimize your energy usage as well as your process and application performance. Thousands of configurations of mixers have been manufactured with our approach.

Bring your needs to our team, we will make it a reality with our process experience.

Dynamix designs this product according to your application and process. Our chemical and mechanical engineers come from various process industries and will work to understand and develop your design requirements.

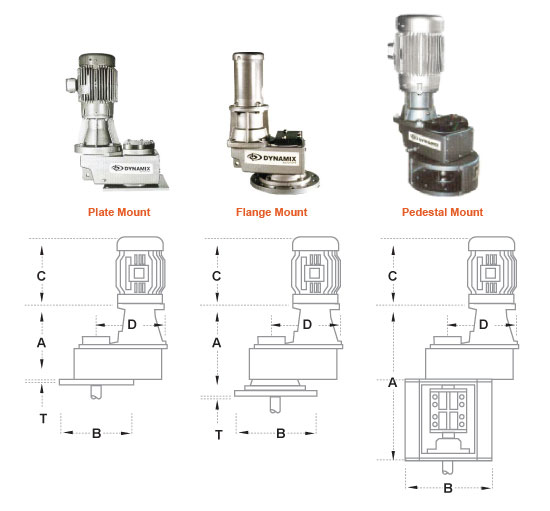

Drop Flange – Easily remove the drive for maintenance without removing the shaft from the tank. Minimize downtime and make your maintenance manager happy, drop flange and seals have access through larger pedestal mounts, as seen on the image here

Locations: Pulp Mill Installations in Crofton, BC and Campbell River, BC – 1999

Don’t like filling out forms? No problem, send us an email directly info@dynamixinc.com

This website uses cookies to ensure you get the best experience on our website