Dynamix agitators' cookie consent authorization

This website uses cookies to ensure you get the best experience on our website

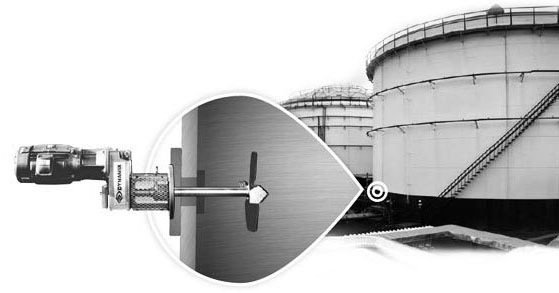

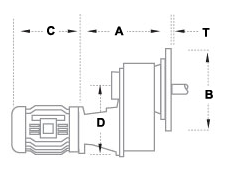

The Dynamix SMX side entry mixers are your best solution for large storage tanks, large basins, or where top entry mixing is not economical or effective. From basic sediment and water applications to heat transfer, we have a configuration for you.

While side entry mixer applications tend to be simple in comparison to top entry mixer applications, there are plenty of environments and processes that require the full configurations capability of Dynamix. Larger side entry tanks tend to be in the harshest environments where tank maintenance is very challenging.

The following options are available with your Dynamix Mixer. Just work with your application engineer to select the best configuration for your tank and process.

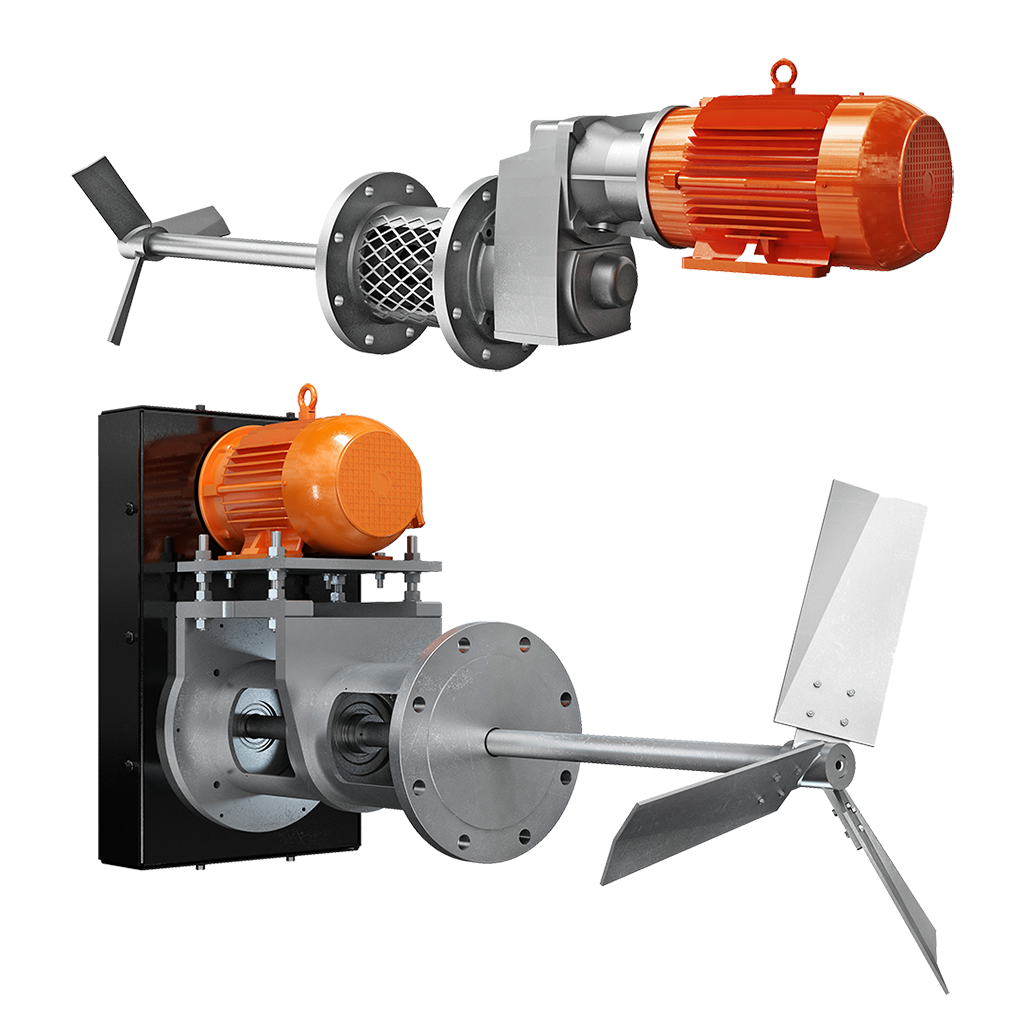

Standard NEMA C-face motors with a power range from 1 to 60 HP. Other motor configurations are available to suit your environment

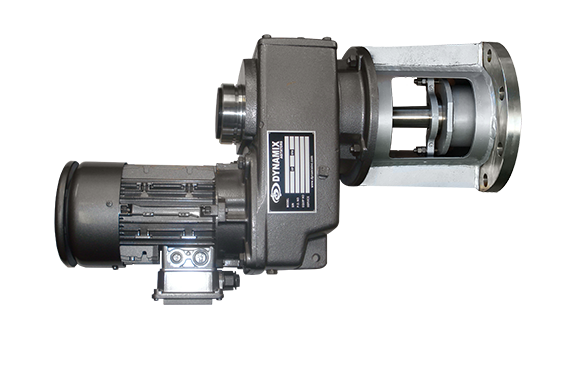

Efficient Performance. 2 stage Helical Parallel Shaft Drive Units are 97% efficient, producing up to 5,841 lb-in of Torque. This is all the pumping and thrust required for the most demanding applications.

These gearboxes are heavy-duty, selected with a minimum service factor of 2.0. When combined with oversized tapered roller bearings, ISO L-10 life will significantly exceed our standard minimum of 100,000 hours.

Have a specific brand in mind? We can install it to match what customers have in their plants.

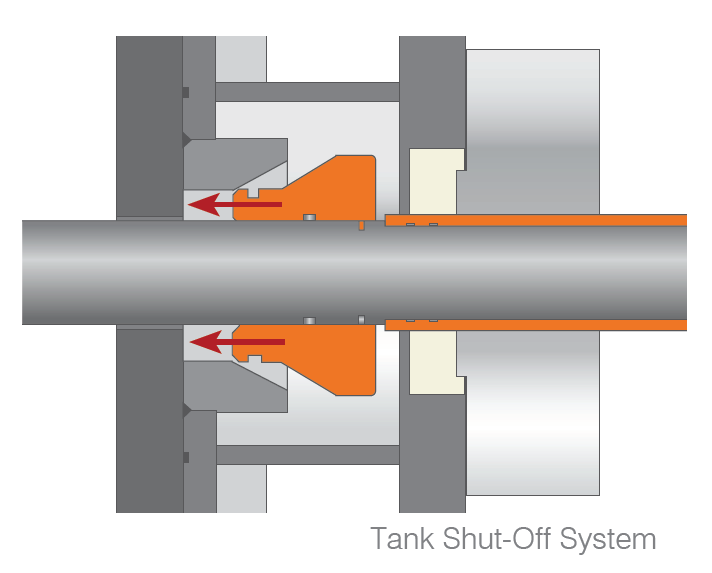

Maintenance. Because storage tanks are so large it is often not an option to draw the tank down for maintenance. Dynamix has designed a tank shut-off mechanism that allows the side entry mixer to be removed without drawing the tank down. Our unique tank shut-off configuration allows you to seal the tank and easily replace the seals without draining the tank.

P3B Modified Pitch-Blade. For higher shear applications, this impeller bridges the higher efficiency of the Dynaflow™ impeller with the more intimate mixing capabilities of a Pitch-Blade.

Dynamix engineers this product line according to your application and process. Our Chemical and Mechanical Engineers come from various process industries and will work to understand and develop your design requirements.

If you are unsure of your industrial tank design…

Don’t like filling out forms? No problem, send us an email directly info@dynamixinc.com

This website uses cookies to ensure you get the best experience on our website