Dynamix agitators' cookie consent authorization

This website uses cookies to ensure you get the best experience on our website

Problems with

SETTLING or

SEPARATION?

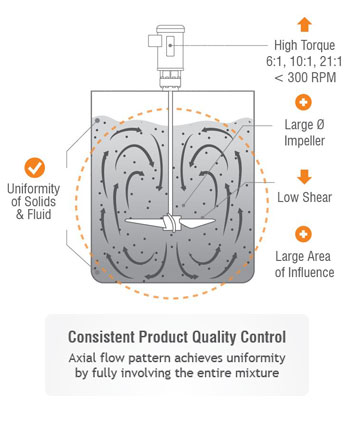

Mixing is a Primary Product Quality Control Tool

When properly sized and selected, your mixer will ensure your product uniformity.

Product Uniformity

=

Product Quality

After defining your mixing objective, we balance the power and pumping requirements of a specific impeller with the torque required to achieve uniformity. Your drive may cost a little more, but the increase in product quality control and savings in process time cover this cost immediately.

By achieving true axial flow mixing, we can guarantee the time to uniformity. This is our process guarantee – Our Solution Assurance.

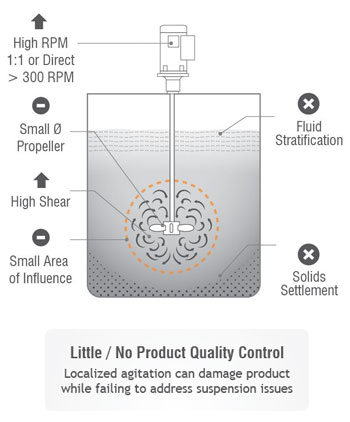

When you use an “off-the-shelf” mixing solution

uniformity and product quality are compromised

Using a high RPM motor with a small propeller introduces high shear – and more importantly, it only creates a small area of influence.

Poor product quality control with an increased risk of product damage, and a mixture that does not reach uniformity.

This information, combined with our mixer engineering, allows us to guarantee your mixing time to uniformity.

This website uses cookies to ensure you get the best experience on our website