Dynamix agitators' cookie consent authorization

This website uses cookies to ensure you get the best experience on our website

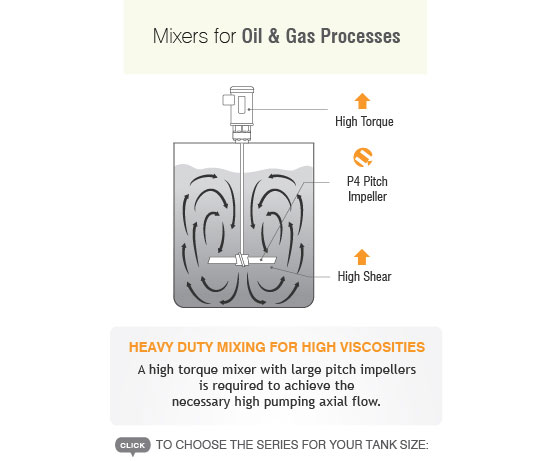

Looking for an oil and gas industrial mixer? Dynamix’s heavy-duty industrial agitators and mixers utilize the most robust gearbox, bearings, and shaft configurations.

Our oil and gas industrial mixers also address ancillary needs such as efficiency, required reactions, environmental, and unique application factors. This is how industrial agitators are engineered into true heavy-duty mixing solutions – the NMX Series.

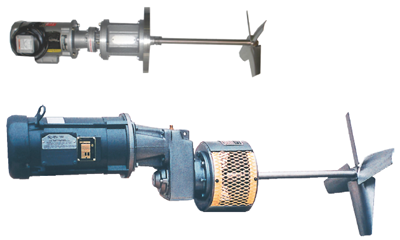

The NMX Series industrial agitator is specifically designed for heavy industrial mixing. Quality components and rugged construction produce long-term, trouble-free operation. The NMX Series agitators are both heavy-duty and highly efficient.

This industrial mixer series is the powerhouse of our line of industrial agitators and is typically applied in heavy industries such as energy and natural resources, and large-scale chemical processes.

Large tank mixers are what our company is known for. The GMX Series mixer is designed to handle all of your large tank mixing needs in an economical configuration, without sacrificing durability or efficiency.

GMX SERIES

High-efficiency design configured for medium-duty applications.

Also available with a low profile, right-angle gearbox. Designed for top entry mixing in industrial oil tanks from 2,500 to 10,000 gallons.

Side entry mixers play an important role in oil storage tank design. The control of sludge and sludge build-up can have a great effect on the tank capacity, as well as safety related to cleaning and later processes.

For this, we use side entry agitators designed for holding tanks. Our SMX Series features thrust impellers, which are highly efficient and ideal for mixing in storage tanks. Further, these mixers are configured with mechanical seals and shut-off valves for ease of maintenance.

Work with our team to configure the right mixer, or cluster of side entry mixers for your mixing process. Getting the right mixers in place will have a great effect on process efficiency downstream.

Oil and gas or petroleum industries are highly dependent on properly designed mixers. Typically, these mixers are either top entry mixers or side entry mixers.

Further, these mixers will follow the oil and gas process from extraction with mixers for drilling mud or fracturing chemicals, to the holding tanks and processing stages.

Knowing when you must use a side entry mixing can save a lot of energy. Knowing how to help suspend sludge in a holding tank will determine efficiencies throughout this process. The oil and gas industrial mixers selection process has never been more important.

No matter what your chemical composition is, our chemical and mechanical engineers will design and guarantee a mud mixer and the time it takes to bring that into uniformity.

Dynamix has a full line of robust industrial oil and petroleum mud mixers for your applications, from drilling mud and fracking fluids to asphalt, crude oil, and gasoline.

Dynamix has various model series to fit your needs:

Our heavy-duty industrial agitators are configured to process your liquid application to your specifications. Dynamix is proud of its mechanical innovation, but our true value to you is in our understanding of your liquid and application.

Dynamix’s experts in oil and gas mixing systems will seek to understand your process, select the right mixer, and provide you with a complete mixing solution. By understanding your process, including blending time, tank design, viscosity and density, we’re able to configure mixers specifically for your application. This in-depth knowledge is what also makes it possible for us to offer our Solution Assurance, which helps you set the uniformity and cycle time of your process.

The result? Uniformity, right when you need it.

MOTOR

Standard NEMA C-face motors with a power range from 1 to 75 HP. Other motor configurations are available.

GEARBOX

The SMX Series side entry mixers for storage tanks have a standard output speed of 300 rpm. With robust helical or helical bevel gearboxes and a minimum service factor of 1.5, these drives are built to last. The gears are constructed of SAE 8620 steel, with a minimum of 58 Rockwell hardness. Ground to AGMA 13 quality rating, the gears will provide quiet, long-term operation.

The rugged shaft support design ensures our side entry mixers can withstand all fluid forces, and the oversized, tapered roller bearings have an L10 life of over 50,000 hours. A strong and rigid, one-piece housing design is crafted from SAE 30 gray iron and features exceptional housing torsional stiffness and a thick housing wall section.

Dynamix’s heavy-duty industrial agitators and mixers utilize the most robust gearbox, bearings, and shaft configurations.

Our industrial agitators also address ancillary needs such as efficiency, required reactions, environmental, and unique application factors. This is how industrial agitators are engineered into true heavy-duty mixing solutions. The NMX Series is a good option in the oil and gas industry when working with tanks or vessels between 2,500 to 300,000 gallons … Learn More

The DMX Series line of industrial mixers is our most widely applied line of mixers. This is a true portable industrial mixer, which can be configured to suit your most challenging applications. The DMX Series is a good option in the oil and gas industry when working with tanks or vessels between 300 to 3,000 gallons … Learn More

Mud mixing is a key component of any oil and gas operation. Control of mud mixing, or drilling fluids can be a significant determinant of a drilling operation as related to wellbore problems. Management of viscosity specific gravity, and chemical composition are key to the mud mixing and the circulation system. Our expertise is in bringing these solutions into uniformity or specification so that your time and investment in the mud mixture is not lost at the plant. Or more importantly – at the site.

The ITM plastic tote mixer is part of a new class of tote mixers. These plastic tote mixers are made possible by several Dynamix innovations. Our impeller technology, mixer mount, and dynamic coupling have enabled the plastic tote mixer to become a process vessel and key quality control tool. … Learn More

Our dynamic coupling technology is used in the fracking, to prepare fracking fluid to be used to be sent done the boreholes and retrieve natural gas. The Dynamix dynamic coupling allows for easy use of one pump on many totes. Check out this great article about it on our Mixing Matters Blog on Fracking and Mixer Use. Tote agitators can be used when batches are too small for processing in a large steel tank. ITM tote agitator designs for steel totes can be designed to make small-batch processing possible…. Learn More

Don’t like filling out forms? No problem, send us an email directly info@dynamixinc.com

This website uses cookies to ensure you get the best experience on our website