Dynamix agitators' cookie consent authorization

This website uses cookies to ensure you get the best experience on our website

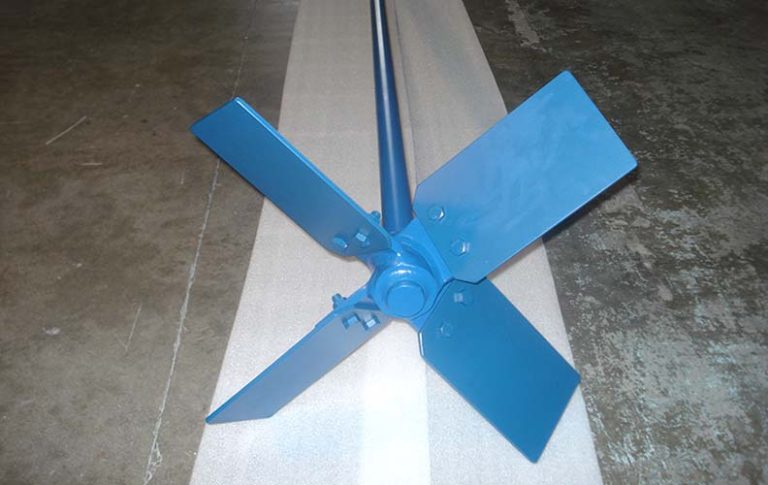

Hydrometallurgical processes and mineral processing in general involve some of the heaviest solids suspensions and slurry processes. Protection from abrasions caused by heavy slurries is critical to the longevity and production of these processes. Our mixers are compatible with all types of wetted materials, and suited for heavy slurry abrasions and demanding applications, i.e., unique alloys and coatings are used for these demanding applications.

In order to ensure your mining equipment is protected from highly corrosive chemicals in your applications, all our mixer’s wetted parts can be constructed with select alloys. We provide a wide variety of abrasion-resistant coatings options, to reduce friction and extend the life of your mixer used in your application.

Hydrometallurgical processes such as ore leaching, adsorption, and solvent extraction are examples of such applications. Such select mining processes and applications that use corrosive chemicals require expert input in designing an agitator that will last.

Many mining applications require mixers that can perform under high temperatures and high-pressure conditions. These demands necessitate specific attention to mechanical seal and pedestal designs. Dynamix mixers are engineered and manufactured to meet the extreme conditions and demands of mining applications described above.

Dynamix was borne out of the extreme demands of the mineral processing industry. Robust design and engineering mixing principles back our high-performance mixers. Our mixers can endure your most challenging mining processes, from rugged processes to corrosive applications.

Dynamix can incorporate a wide variety of abrasion-resistant coatings to the wetted parts, e.g., rubber coatings, PVDF coatings, Teflon coatings, and more. These coatings reduce friction and extend the life of your mixer in application. Select mining processes and applications that use corrosive chemicals require expert input in designing a solution to ensure equipment is not damaged in such challenging mixing environments.

Work with our mining mixer experts to design a heavy-duty mixer for your mining and refining project: from ore leaching, to counter current decantation, to flotation, to conditioning, and attrition scrubbing processes, and more.

Don’t like filling out forms? No problem, send us an email directly info@dynamixinc.com

This website uses cookies to ensure you get the best experience on our website