Conditioning & Mixing Tank Agitators – Mining & Mineral Processing

In the dynamic realm of mining and mineral processing, the

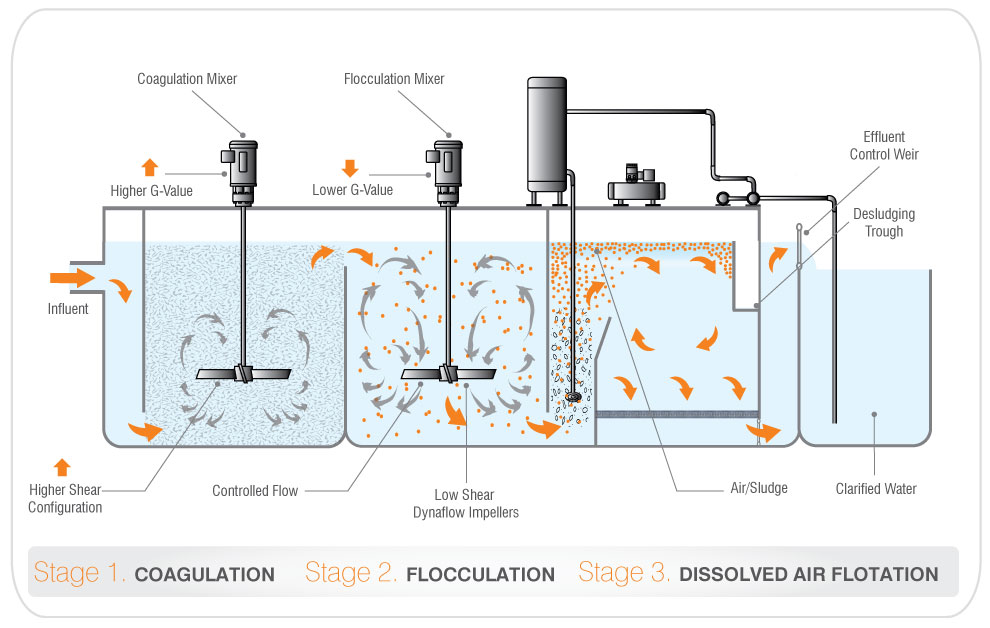

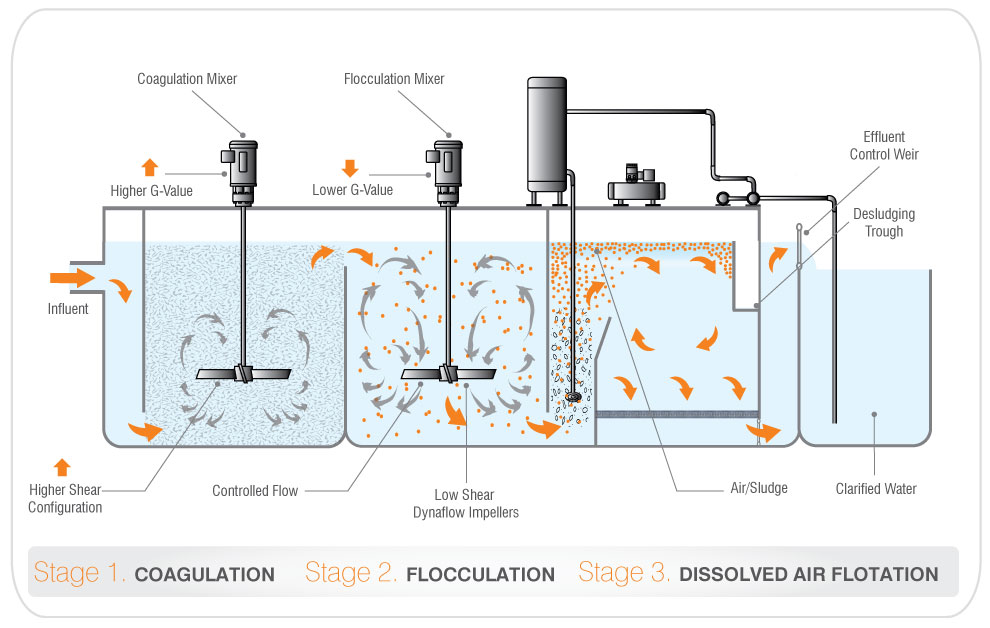

Wastewater has particulate matter which must to be removed before further treatment and clarification, these particles (colloids) are negatively charged. Such particles are very minute and take a very long time to settle. The help increase the time for these particles to settle from a weeks or hours to a few minutes the coagulation process has to be applied early in the water treatment stage.

Generally the coagulation stage happens after the Ph adjustment stage, where the water is adjusted to be more alkaline, so that additives like aluminum sulphate or ferric sulphate (trivalent coagulants) can be effective for coagulation and flocculation process.

Coagulation Process

The objective is to create microfloc from particulate matter, agglomerate the particles, so that it can settle and move to the sedimentation process. The particulate matter non settleable particulate matter in surface water carries a negative charge. To neutralize negatively charged particle, add a coagulant that is positively charged. This coagulant could be aluminum sulphate. With the addition of this, within a few seconds micro particles are created of as the negatively charge particles bond with the positively charge alum. Once the particles are neutralized the become microflocs, as further mixing continues the become bigger and form macro flocs that can settle to the bottom. At this stage the mixer power is usually high as flash mixing is essential to get the microflocs to ultimately floc together to create larger macroflocs, which a size more conducive to settling.

Flocculation Process

At this stage, another chemical can be added, a polymer, which helps keep the macro flocs together. Essentially it helps make the bridge between the micro flocs stronger when forming the macroflocs.

A Flocculator

3 or more basins with separate mixers. At each stage there are various sizes of flocs, as the size of the flocs increase, the power on the mixers is decreased, to prevent shear, and not damage the flocs. Taking each flocculator stage, various impeller configurations are used.

1st Basin – Microflocs developing into Macroflocs

At this stage the more particle collisions the faster the flocculation process, thus the higher mixing energy results in more collisions per second and helps a more rapid flocculation process.

2nd Basin – Medium sized Macroflocs

At this stage the flocs become larger and thus the mixing energy has to be reduced, as the flocs are larger and are more fragile.

3rd Basin – Larger Macroflocs

At the last basin where the flocs are biggest is where the flocs are ready to move to the sedimentation basin. The low mixer power and flow help maintain the flocs and improve settling for the next stage.

The configuration of the mixers at various stages in the flocculator requires various distinct combinations of impellers segments and drive segments. Dynamix has configured many wastewater mixers for such applications. The application engineers will help establish the optimal combination of mixers for your flocculator. Call us today.

In the dynamic realm of mining and mineral processing, the

Mining operations are essential for meeting the world’s resource needs, yet they

Water treatment is a complex yet vital process that ensures

Subscribe to our newsletter for helpful technical publications and industry announcements.

This website uses cookies to ensure you get the best experience on our website