Conditioning & Mixing Tank Agitators – Mining & Mineral Processing

In the dynamic realm of mining and mineral processing, the

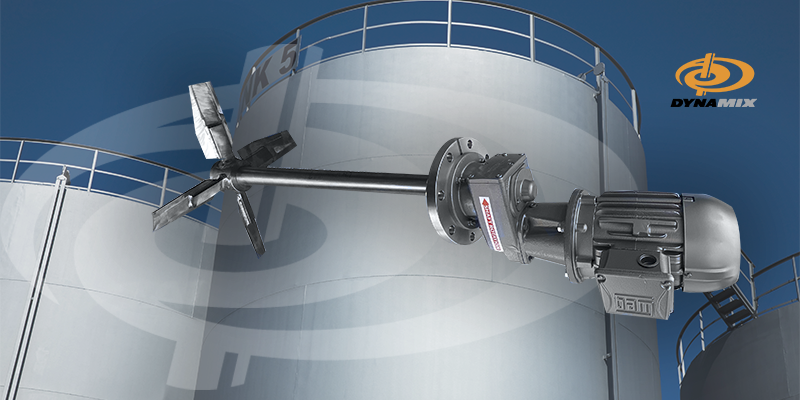

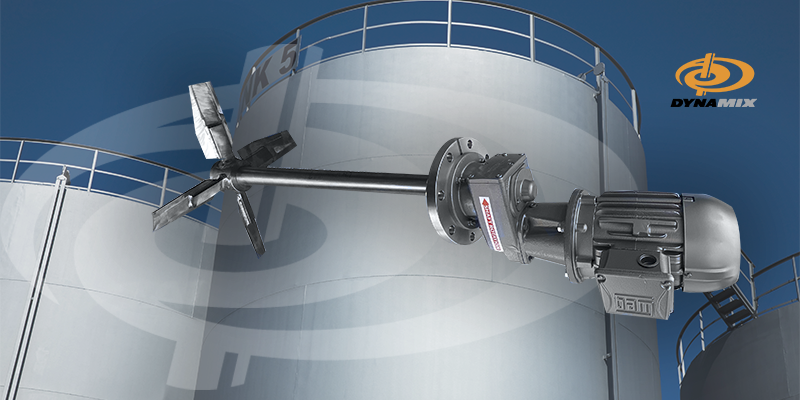

While top entry mixers are most common in Industrial Processing, many of the same industries require Side Entry Mixers. These mixer are common to Petrochemical, wastewater treatment, mining, and agrochemical processes which implement side entry mixers to meet storage and blending requirements. But, knowing which processes need side entry or top entry can result in massive energy savings, and process control. Dynamix designs versatile mixers with unique features to meet your process requirements.

The decision to use side entry rather than top entry mixers is based on careful evaluation of process requirements and the impact on product quality and capital and operating costs. The most common applications for side entry mixers are storage or blending tanks where the tank diameter is greater than the tank height. In addition to these cases, a side entry mixer is sometimes the only possible solution when clearance or a floating roof prohibits installing a top entry mixer.

One of the most significant design considerations when implementing side entry mixing is turnover. Top entry mixers provide powerful axial pumping. When properly designed, this prevents dead zones and short-circuiting, delivering turnover for the entire tank volume. Side entry mixing instead pumps along the horizontal, leading to poor homogeneity if not handled correctly.

Mixer configurations often entail several mixers at different positions and angles. Optimal configurations avoid the formation of vortexes and provide sufficient vertical turnover to maintain a homogeneous composition throughout the tank.

Maintenance is a significant design challenge for processes that implement side entry mixing. These mixers rely on complex mechanical seals to prevent any leakage. These components increase both the required capital expenditure and the ongoing maintenance cost.

Side entry mixing can lead to significant downtime during any maintenance. Because removing the mixer leaves the entry point on the side of the tank open, product must be drawn down before removal. In order to solve this problem, Dynamix has developed a unique tank shut-off system for our SMX line of side entry mixers. This configuration allows the tank to remain full while maintenance is performed on the mixer. This can significantly reduce downtime during maintenance due to the ability to seal the tank during mixer maintenance.

Dynamix provides side entry mixers for any process. Every side entry mixer we produce is carefully designed by our team of engineers for your unique process requirements. We provide solutions for tanks ranging from 2,500 to 300,000 gallons, with numerous drive and gearbox options.

The SMX line includes options for any facility, from economy models to the most robust and specialized mixers available. Our team can design a side entry mixer with the right impeller, seal, drive, position, and angle for your specific needs and budget.

The engineers at Dynamix develop optimal side entry mixers for your blending and storage process applications. You can reduce your maintenance and operating costs with our tank shut-off system and efficient Dynaflow™ impellers. We design mixers for all applications, so contact Dynamix today to see what our team can do for you and a quote on your mixing needs.

In the dynamic realm of mining and mineral processing, the

Mining operations are essential for meeting the world’s resource needs, yet they

Water treatment is a complex yet vital process that ensures

Subscribe to our newsletter for helpful technical publications and industry announcements.

This website uses cookies to ensure you get the best experience on our website