Conditioning & Mixing Tank Agitators – Mining & Mineral Processing

In the dynamic realm of mining and mineral processing, the

In the process industry, there’s a strong focus on power as the defining characteristic in mixing. Many considerations are often left by the wayside when choosing a mixer. These factors can make or break the application. Relying solely on the G-Value or velocity gradient in mixer design leaves important information out of the equation.

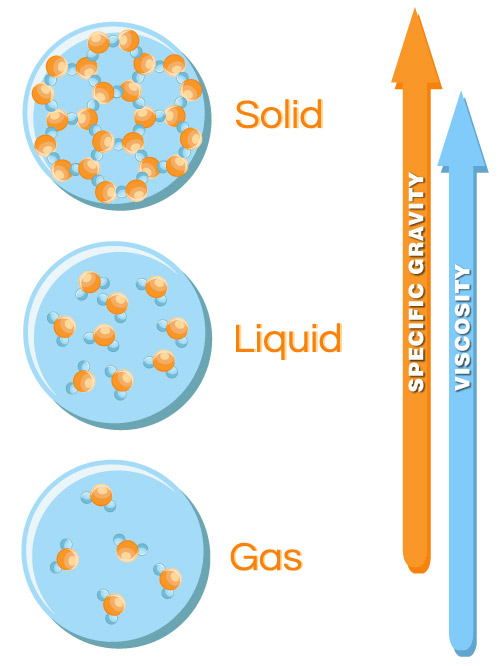

Focusing on the G-Value gives rise to the misconception that horsepower, rather than torque, is the critical factor determining mixing effectiveness. This method is effective for applications requiring high-sheer and turbulent flow, but this isn’t always the case. High-speed mixing introduces a host of additional considerations based on fluid viscosity, flow patterns, and shearing.

Different types of mixing have different requirements. It’s important to understand these requirements to determine which applications can benefit from low-speed mixing over high-speed mixing.

This category involves the dispersal of solid components, whether they’re powders, pigments, dyes, or polymers, into a liquid through mixing. Applications include adsorption, polymerization, crystallization, solid-catalyzed reactions, and also activated sludge processes. High shear and axial flow serve to disperse solids and counteract settling. There are two types within this category:

Suitable for promoting chemical and also bioorganic reactions, this category of mixing disperses low-density compressible gas within a liquid. High detention times provide more significant contact between gas bubbles and the liquid. Typical applications include chlorination, hydrogenation, organic oxidation, in addition to carbonated water production for soft drinks. Complex interactions between gases and liquids can increase or decrease viscosity, requiring diverse mixing strategies.

Many fluid dynamic characteristics affect this mixing category. Flow pattern and turbulence, breakup, coalescence, and suspensions of drops, along with the interfacial area and drop size distribution, all play a role. The critical parameters in liquid-liquid mixing are mixing time and circulation time. Circulation time is a product of the mass fluid motion through pumping. Correspondingly, mixing time is affected by impeller speed and diameter, vessel size, baffle placement, and also fluid properties. Liquid-liquid mixing falls into two categories:

The varied categories of mixing have unique applications, goals, and obstacles. These applications require diverse approaches, and in many cases, low-speed mixing is more suitable than high-speed.

These different types of mixing have a common principle, the transfer of energy from a power source to the product within the process. Adequate mixing requires fluid circulation throughout the volume of the tank within a reasonable time. The basic design of the mixing process involves impeller or blade design, shaft speed, torque, tank geometry, as well as fluid viscosity.

Different impellers have different flow characteristics. As the impeller imparts energy to the process, that energy goes into both the primary flow within the tank and fluid shear. The amount of energy that dissipates as fluid shear is a critical factor when choosing the correct impeller for a specific application. Some processes, such as aeration, require high shear, while others do not.

Flow type is primarily determined by impeller or blade design:

Blade types used in low-speed mixing are flow, pressure, or shear impellers. Low-speed mixing with a large blade is suitable for high flow processes. A smaller impeller at high speed produces high shear. Gate blades provide high flow and low shear, while radial flow turbines, bar turbines, and flat blades provide higher shear compared to flow.

During mixing, the tip of the impeller moves fastest and imparts higher velocity to the fluid. Closer to the shaft, there is less shear. The velocity gradient increases correspondingly to the shear rate. Shear stress produces localized mixing and circulation. The proximity of the blades to the wank walls and bottom also affects shear.

Tank Design for Optimal Mixing

Tank Design for Optimal MixingChoosing between low speed and high speed mixing significantly affects tank design. Low-speed mixing generates substantial flow, requiring an increased diameter to wall height ratio. In applications that must keep a large volume tank of a product within specification, a large impeller running at low speed at the bottom of the tank maintains suspension and uniformity.

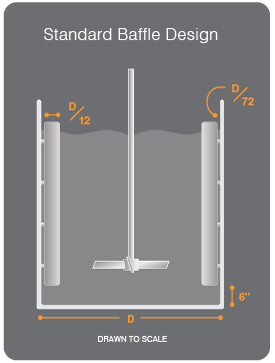

Optimally, a tank designed for solids suspension will be round with an aspect ratio of 1:1. Tank geometry impacts the design and cost of industrial agitators, with 1:1 providing the most economical options. The mixer can be center mounted or angle-offset mounted. Baffles are important to this type of tank design for low viscosity fluids. However, they are not necessary for high viscosity fluids where viscous drag is present. Baffles produce shear that can lead to de-stratification, which might not be desirable in some mixing applications.

| Marine Propellers A marine propeller the ideal choice for low shear, high-speed mixing. It is well suited to low viscosity direct drive mixers. With the same design that provides propulsion for watercraft, a marine propeller comes the closest to achieving purely axial flow. A marine propeller imparts significant rotational momentum and is typically fitted to a tank with baffles or mounted in an offset position. |

|

| Axial Flow Turbines Axial flow turbines see use in applications that require both flow and shearing, particularly viscous mixtures. Optimal depth is at half the turbine diameter from the tank floor, or 1/3 of the fluid depth when mixing dissimilar fluid combinations. A shaft with two stacked axial impellers is suitable for tanks where the depth is more than double the diameter. |

|

| Axial Hydrofoils A recent innovation, axial hydrofoils twist each vane’s pitch to maintain constant flow across the length of the blade. Derived from the design of aircraft propellers, the shape reduces overall turbulent eddy currents and increases the power factor. Although expensive, the increased efficiency could reduce the required drive to offset the cost. Hydrodynamic equilibrium requires a higher mounting on the shaft than with an axial turbine, making this design less suitable for some batch applications. |

|

| Radial Turbines A radial turbine is simply flat vertical blades welded to a hub. Fluid discharges at right angles to the shaft, forming two flow tori above and below the blade, similar to a high-speed disperser. This design produces significant turbulence, ideal for gas dissolution and light dispersion applications. The vanes can be swept back relative to the plane of rotation, creating less turbulence and using less power. These designs are for mass movement in large tanks. Radial turbines are almost always used in tanks with baffles, except in small tanks where the tank wall proximity effect comes into play. Baffles serve to redirect radial flow up and down within the tank. |

|

While high shear dispersers certainly find use in a wide variety of applications across different industries, low-speed mixing is the ideal solution in many cases. Increased energy savings and efficiency in large volume applications make them a viable option in many designs, along with gentler handling of specific formulations.

The key to designing any system is to choose the right impeller and provide appropriate power to the system. With low-speed mixing, induced flow in the fluid greatly increases an impellers pumping capability. Correctly designed, a low-speed mixing system can provide sufficient flow to utilize the maximum basin volume properly and effectively distribute incoming flow.

In the dynamic realm of mining and mineral processing, the

Mining operations are essential for meeting the world’s resource needs, yet they

Water treatment is a complex yet vital process that ensures

Subscribe to our newsletter for helpful technical publications and industry announcements.

This website uses cookies to ensure you get the best experience on our website