Conditioning & Mixing Tank Agitators – Mining & Mineral Processing

In the dynamic realm of mining and mineral processing, the

In a perfect world, the only industrial mixing projects we would ever work on would be applications in cylindrical tanks where we could center-mount the mixer. That, of course, is not typically the case. Instead, factors such as environment, process design, tank design, and process objective require different mounts. For this, we offer our 40+ years of experience and engineering to develop mounting options to address almost every eventuality.

Ultimately, the mounting option is dictated by the need to manage the reactionary force generated by the mixer’s torque at the fluid level inside the tank. High viscosity liquids, or large volume tanks that require large diameter impellers, are examples that require a robust and solid mounting to maintain the performance and stability of the mixer. Our Selection Programs are based on basic engineering principals which enable our engineers to calculate, design and or select the right mounting configuration.

The placement of the mixer is also a key consideration. The geometry of the tank and the flow dynamics generated by the mixer will determine where the mixer is placed for the most effective mixing. Some of our larger industrial mixing projects where rapid mixing is desired, or in the case or large quenching tanks where the mixer is acting as a pump are just two examples. Again, we use support programs such as CFD (Computational Fluid Dynamics) to position, design and select the best mixer mount.

As a basic starting point always review the following:

We offer the following options when determining your mounting requirements:

Tank Mixers |

|

|

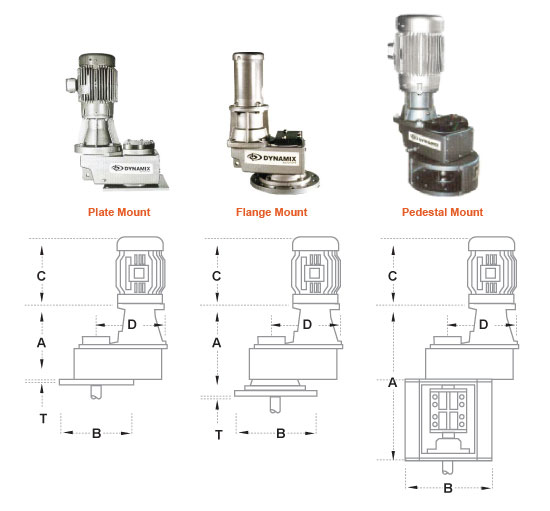

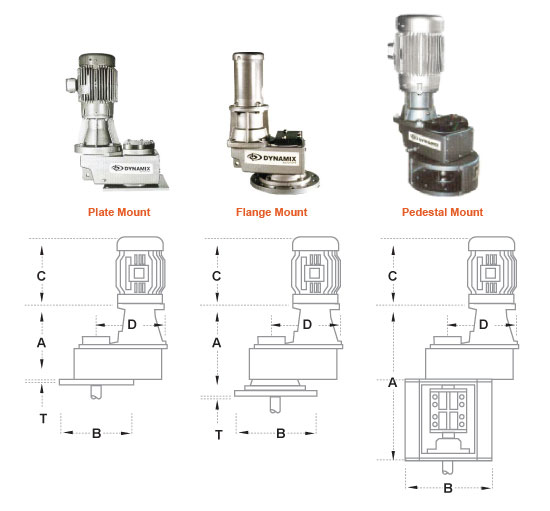

Plate Mount Standard plate to mount on beams over open-head tanks |

|

Flange Mount Standard ANSI pipe flange to mount on closed-head tanks; for non-pressurized tanks |

|

Drop-Flange Mount For large industrial agitators to allow the shaft & drive section to be separated so that the shaft rests on the flange & gearbox can be take off for service |

|

Pedestal Flange Mount Pedestal mount to house stuffing box or mechanical seals for pressurized tanks |

|

Side-Entry Flange Mount For side-entry tank agitators |

|

Heavy-Duty Clamp Mount Keyed for secure positioning through 30 degrees on the horizontal axis allowing maximum flexibility |

|

Light-Duty Clamp Mount Keyed for secure positioning through 30 degrees on the horizontal axis allowing maximum flexibility |

Tote Mixers |

|

|

Bridge Mount Bridge mount to be installed over tank suits all major brands of plastic totes |

|

ITM Tote Mount This plate mount fully encloses the tote container with the cap. With the ITM coupling, there is no need to open the tank again for shipping or mixing. Total quality control |

Drum Mixers |

|

|

Universal Drum Mount Unique universal design for mixing in either Open or Closed Head drums with the same mixer, angle mounted to allow for larger diameter collapsible impellers |

|

Drum Lid Mount Standard design includes steel drum lid to mount on drum or barrel, with either Center Mount for solid suspension and high viscosity applications, or Offset Mount to enable the baffling effect |

|

Bung Mount Standard 2”NPT bung port mount for fully enclosed mixing, collapsible impellers expand internally to provide increased mixing in closed head drums and totes |

In the dynamic realm of mining and mineral processing, the

Mining operations are essential for meeting the world’s resource needs, yet they

Water treatment is a complex yet vital process that ensures

Subscribe to our newsletter for helpful technical publications and industry announcements.

This website uses cookies to ensure you get the best experience on our website