Conditioning & Mixing Tank Agitators – Mining & Mineral Processing

In the dynamic realm of mining and mineral processing, the

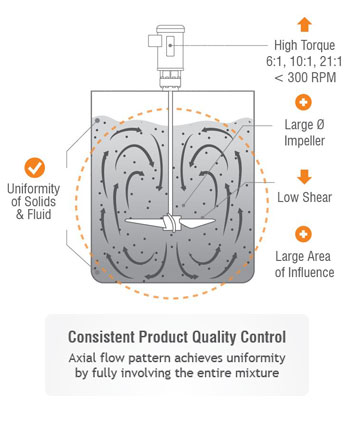

Achieving a uniform dispersion of solids in a product

is critical to your product’s quality.

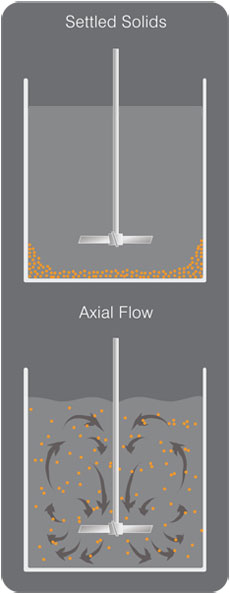

In processes that mix solids in fluid, particulates that cannot dissolve in liquids will either sink to the bottom of the tank and collect in the corners, or stick together and agglomerate. This compromises product uniformity (product quality), and in extreme cases, can cause a system to malfunction or fail.

The main objectives of solid and liquid solutions are:

The goal is to bring the mixture into specification and keep it there. This means keeping the solids evenly dispersed throughout the product, without damage.

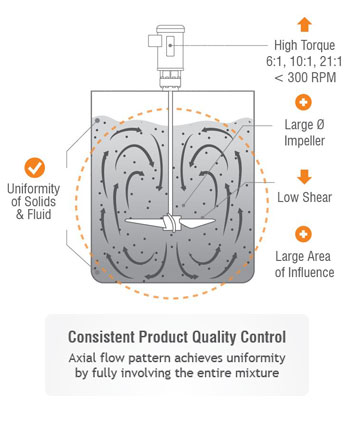

All impellers are designed to “pump” fluid and create turbulence within a mixing vessel. Both of these effects are essential to mixing. Pumping and turbulence produce fluid velocity and fluid shear respectively.

Two key factors to consider during mixer configuration are settling rate and suspension quality.

When sizing a mixer for applications that require solids suspension, we need to calculate the settling rate of the particles. Two components that affect the settling rate are:

The solid settling rate is crucial as it affects the amount of pumping required for the appropriate level of suspension to be achieved, therefore impacting the configuration of the mixer.

The level of suspension, or suspension quality, required in an application is generally determined by how uniform the product needs to be. Suspension quality is achieved using the degree of pumping necessary. The higher the pumping the higher the mixing intensity, which is usually categorized as mild, medium, and vigorous. As the pumping level increases so does the level of uniformity.

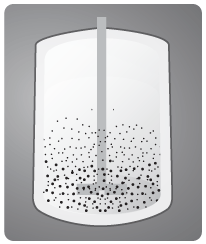

Let’s take a closer look at the three levels of suspension quality that can be achieved in mixing:

|

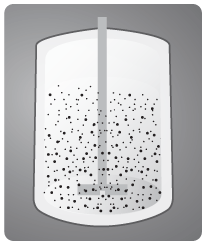

|

|

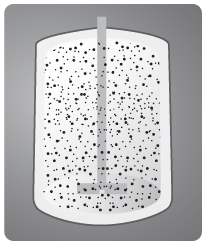

|

|

|

Each level of suspension quality depends on complex interactions of impeller generated flow, turbulence, and solid loading. Although there are multiple factors to consider in solid/liquid systems, mixer configuration for this process always begins with impeller selection.

Correct impeller design is crucial to reaching and maintaining the quality of an application. Impellers that create an axial flow deliver a superficial velocity and an upward pumping action necessary to ensure that solids remain in suspension.The rate of the flow in a tank needs to be greater than the solid settling rate. And the level of superficial velocity achieved will determine the suspension quality created in the tank.

If you’re interested in learning more about mixing solutions for solid-liquid applications, post a comment or email us at info@dynamixinc.com. |

|

In the dynamic realm of mining and mineral processing, the

Mining operations are essential for meeting the world’s resource needs, yet they

Water treatment is a complex yet vital process that ensures

Subscribe to our newsletter for helpful technical publications and industry announcements.

This website uses cookies to ensure you get the best experience on our website