Identifying Mixing Opportunities

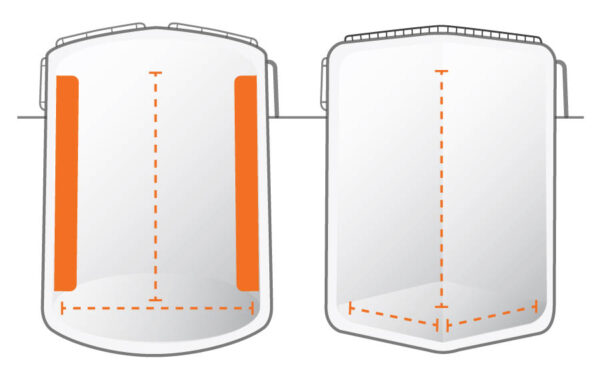

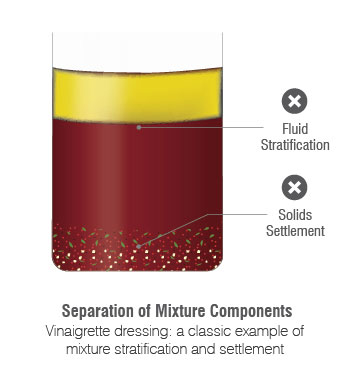

Identifying Mixing Opportunities Mixing, Like Oil & Vinegar… To identify potential mixer applications for liquid products, consider the composition of oil and vinegar salad dressing, as it depicts the two greatest challenges addressed by mixing: separation of non-miscible fluids and the settling of solids. Settling & Separation Any liquid that separates or settles over time is an opportunity for a mixer application. For these liquids, which are known as non-homogeneous, maintaining their uniformity is critical to maintaining their quality. If a product isn’t brought into uniformity in production, or just before it’s used, the quality of that product is lost. That’s why oil and vinegar salad dressings need to be shaken before consumption. Without shaking, you’d have to eat the