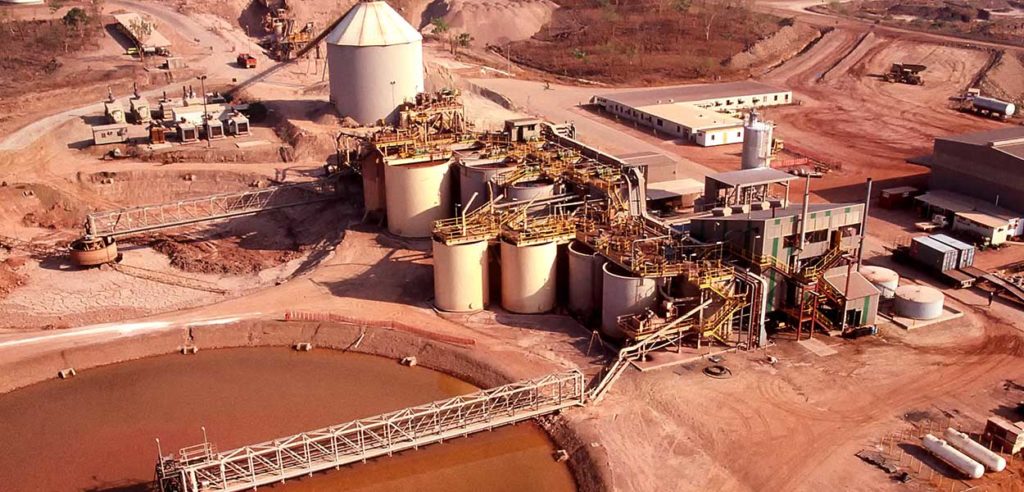

Most jurisdictions around the world require remediation of cyanide and cyanide metal complexes in gold leaching tailings. Whether through cyanide destruction or cyanide recovery, an additional step is added to the process. There are many distinct chemical processes for cyanide remediation, each presenting unique challenges. Dynamix’s GMX and NMX lines can provide engineered cyanide destruction agitators for any size or type of operation.

Cyanide Destruction Agitators for SO2/Air Processes

The most widespread cyanide destruction technique in current use is the INCO process. The process supplies SO2 and air, or oxygen, in order to convert free cyanide and cyanide in metal complexes to cyanate. Cyanate, an oxidized form of cyanide, is significantly less toxic and is suitable for discharged to the tailings dam. Because this reaction relies on gas to liquid mass transfer for contact between reagents, agitation is of primary importance.

Cyanide destruction agitators for the INCO process have three main requirements, blending, solids suspension, and gas dispersion. All three serve to increase contact between reagents, increasing reaction rate and reducing the required retention time. As SO2 gas and air enter the tanks, agitation disperses the gas for improved contact. The significant volume of gas introduced presents a risk of impeller flooding, where the impeller only contacts gas instead of liquid. Impellers must be designed carefully for specific process conditions to avoid flooding.

At Dynamix, our team of engineers understand the specific mixing demands of cyanide destruction processes. Years of experience with the mining industry enable us to implement effective and efficient solutions. Our GMX and NMX agitators provide the high pumping and low shear agitation necessary for uniform solids suspension and gas dispersion. We can design impellers with the optimal diameter, blade type, and configuration to avoid flooding under your unique process conditions.

Dynamix Solutions for All Cyanide Remediation Methods

While the INCO process is the most common, many other processes present their own challenges for cyanide destruction agitators. Cyanide recovery processes are seeing wider use. Acidification, volatilization, and reneutralization (AVR) and newer SART processes involve the conversion of cyanide to hydrocyanic acid, which is then stripped with air. These processes rely on agitation in order to achieve the required blending and gas dispersion.

Similarly to the INCO process, most cyanide destruction methods rely on the oxidation of cyanide to cyanate, whether through the addition of powdered, dissolved, or gaseous oxidants. Methods like alkaline chlorination and hydrogen peroxide require substantial blending to achieve the highest possible mass transfer. Ozonation, much like the INCO process, requires gas dispersion. Dynamix’s team of engineers can provide custom agitators for any cyanide destruction or recovery processes.

An Engineered Solution to Meet Your Unique Requirements

Dynamix provides engineered solutions for cyanide destruction agitators and any other agitator and mixer demands in the gold leaching process. The NMX line of agitators suits tanks up to 300,000 gallons, with the GMX line providing solutions up to 10,000 gallons. We provide optimal impeller design through the use of computational fluid dynamics to ensure the proper velocity gradient and shear for your process. Contact us today to see how our solutions can improve your process.