Conditioning & Mixing Tank Agitators – Mining & Mineral Processing

In the dynamic realm of mining and mineral processing, the

Bitumen Production and Characteristics

Bitumen, also known as asphalt, emerges either naturally or as a residue during crude oil distillation. It consists of complex hydrocarbon compounds, varying in metallic, sulfurous, nitrogenous, and oxygenated elements. Its applications span road construction, paint, and water-resistant coatings. This blogs talk about production of bitumen and importance of mixers.

Dynamix Agitators holds exceptional and exclusive expertise in blending Bitumen. Moreover, our innovative mixer design approaches have been developed to optimize the Bitumen Delivery Process effectively at the plant.

Bitumen Production Processes

1. Distillation Process

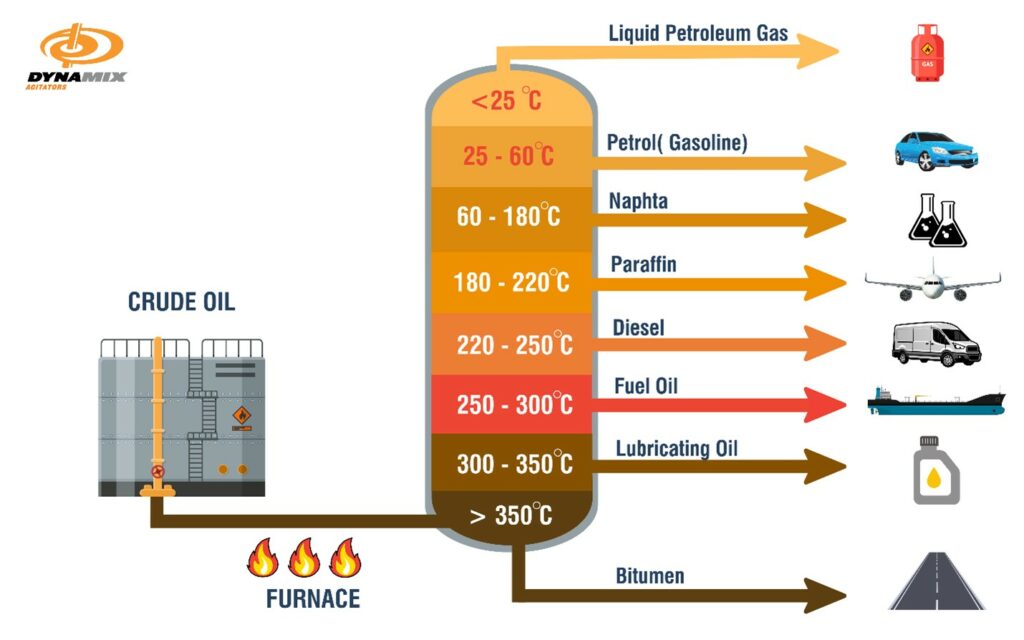

The primary method involves crude oil distillation, where specific bitumen properties are achieved by carefully selecting crude oil feed and operational conditions. Distillation separates lighter fractions, leaving behind the atmospheric residue that undergoes vacuum distillation. This process enables control over bitumen hardness variations.

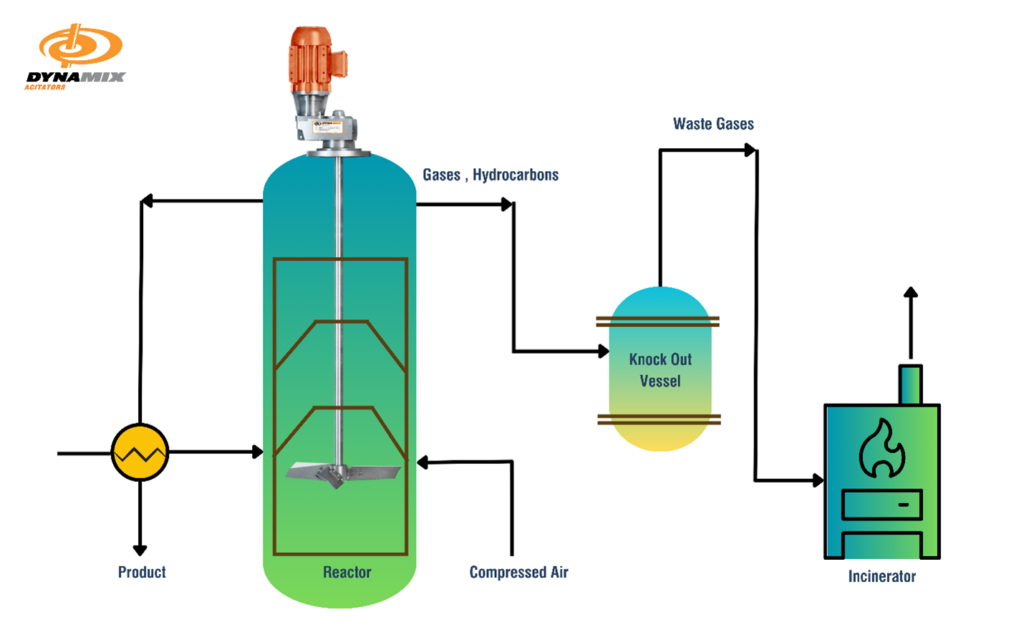

2. Aeration or Oxidation

To alter bitumen’s physical properties further, aeration or oxidation is employed. Blowing air through the residue at elevated temperatures in a specialized unit modifies the bitumen, impacting its grade and characteristics. The level of asphalt oxidation determines the range of bitumen grades produced.

3. Blending

Blending involves mixing high and low viscosity residues to meet desired specifications and create various bitumen grades. Additionally, blending polymers with bitumen results in Polymer Modified Bitumen (PMB), enhancing its strength, cohesiveness, and resistance to fatigue and deformations.

Bitumen Grades and Applications

Bitumen Emulsions: These stabilized suspensions of bitumen in water find use in multiple industrial applications. Emulsions offer ease of handling without requiring significant heating, utilized for various purposes in road construction, such as tack coats, fog seals, and bituminous surface treatments. They are non-flammable or explosive in the presence of water.

Polymer Modified Bitumen (PMB): A blend of bitumen and selected polymers, PMB augments bitumen’s properties, providing enhanced strength, resilience, and durability. Especially useful for heavy-duty traffic roads, airfields, and extreme climatic conditions like hot deserts.

Understanding the intricate processes involved in bitumen production within petroleum refineries allows for tailored bitumen grades catering to diverse industrial needs. From enhancing road quality to providing durable waterproofing solutions, bitumen continues to be a pivotal material across various sectors.

The Essential Role of Mixers in Bitumen Production

Bitumen stands as a foundational material in the construction industry, particularly in the creation of road pavements. This sticky, black substance, derived from petroleum through a refining process, boasts remarkable versatility and wide-ranging applications.

The journey of bitumen starts with crude oil distillation. Throughout the refining stages, various components like gasoline, diesel, and lubricants are separated, with bitumen emerging as a residue during the final separation stage, known as vacuum distillation or vacuum residue process.

However, this raw form of bitumen requires further processing to optimize its properties. This involves the addition of diverse additives, such as polymers, aimed at bolstering its strength, elasticity, and overall durability. These enhancements are pivotal in tailoring bitumen for specific applications and weather conditions.

The role of mixers in the production of bitumen cannot be overstated. These apparatuses are fundamental in ensuring the thorough and consistent mixing of bitumen with additives and other essential components. Given the highly viscous nature of bitumen, achieving effective mixing can be challenging without the aid of mixers. Their function is pivotal in guaranteeing the desired quality and uniformity.

Temperature regulation during the mixing process is another critical aspect. Bitumen necessitates heating to decrease its viscosity and enable seamless blending with additives. Mixers are equipped with heating elements or steam jackets that supply the requisite heat to maintain optimal temperatures for effective mixing.

Moreover, mixers contribute significantly to achieving proper air entrainment and foam formation in the production of bitumen emulsions. These emulsions, water-based formulations widely used in road construction, rely on mixers to create, and stabilize them, ensuring an even distribution of bitumen particles in water.

To summarize, mixers serve as indispensable components in the production of bitumen by facilitating thorough mixing, temperature control, and the creation of bitumen emulsions. Their utilization is paramount in ensuring the consistent quality of bitumen, thereby solidifying its crucial role in the construction industry.

Bitumen, a versatile black viscous substance derived from crude oil distillation, serves various industrial purposes, from paving roads to waterproofing. Its production involves intricate processes within petroleum refineries, crucial for generating diverse bitumen grades suited for different applications.

In the dynamic realm of mining and mineral processing, the

Mining operations are essential for meeting the world’s resource needs, yet they

Water treatment is a complex yet vital process that ensures

Subscribe to our newsletter for helpful technical publications and industry announcements.

This website uses cookies to ensure you get the best experience on our website