The Gold Mining industry relies heavily on industrial mixers in the Gold Leach CIP and CIL processes. CIP stands for carbon in pulp, while CIL stands for carbon in leach. Both processes involve extracting gold from ore by dissolving it in a solution containing cyanide and adsorbing it onto activated carbon, which creates the ideal carbon makeup.

Mixers play a crucial role in these processes by facilitating the mixing and agitation of the slurry in the tanks. Here, we will explore the importance of industrial mixers in gold leaching and recovery processes.

Mixing and Agitation in Gold Leaching

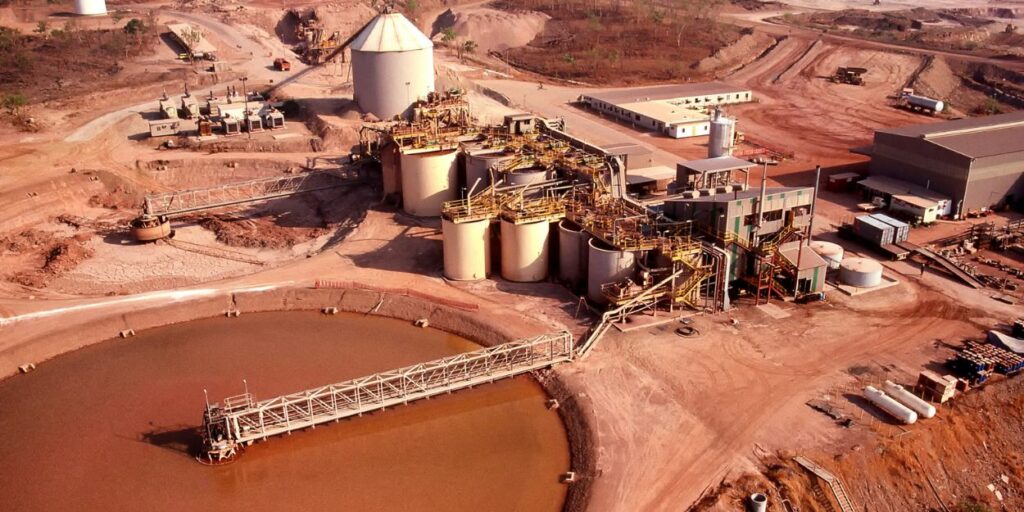

Gold leaching is the process of extracting gold from ore using a cyanide solution. In this process, the slurry of ground ore and cyanide solution is mixed and agitated in tanks. Air is also sparged into the solution to optimize the leaching process. Industrial mixers are used to ensure the even distribution of the leaching solution throughout the ore, optimizing the leaching process’s efficiency. The mixer’s role is to promote the contact between the solution and the gold particles, enhancing the dissolution of gold in the cyanide solution.

Optimizing the efficiency of the leaching process is crucial in gold extraction. The mixer’s design must ensure that the slurry is evenly mixed, the solid particles are kept in suspension, and the cyanide solution is evenly distributed throughout the ore. A poorly designed mixer can lead to uneven distribution of the solution, leading to incomplete gold extraction and a lower recovery rate.

Carbon-in-pulp (CIP) and Carbon-in-Leach (CIL) Processes

In the Carbon-in-Pulp (CIP) and Carbon-in-Leach (CIL) processes, activated carbon is added to the slurry to adsorb the gold particles. The slurry is then mixed and agitated using industrial mixers to ensure even distribution of the activated carbon. The mixer’s role in this process is critical as the adsorption process relies on the even distribution of the activated carbon throughout the slurry. Getting the right activated carbon makeup is important, as poor mixing can lead to carbon sanding or the flow-through of gold to the tailings, resulting in higher costs and reduced efficiency.

The CIL process involves leaching the ore with oxygen and cyanide to dissolve the gold particles, followed by adsorption onto activated carbon. The slurry is then mixed and agitated to ensure the even distribution of the activated carbon, optimizing the adsorption process’s efficiency.

Importance of Industrial Mixers

Engineered Mineral Mixing Solutions From Dynamix

Dynamix Agitators is a leading and reliable supplier of mixers for gold leach processes. Our company has successfully installed thousands of mixers in different climate zones worldwide, and we have consistently met or exceeded our customers expectations in terms of both process and mechanical performance.

Our proven expertise and experience over 45 years in this area make us the industry standard, we manufacture a wide range of mixers from 0.25hp to 500hp Industrial Agitators. We are committed to providing high-quality and customized solutions to meet the unique needs of each customer.