MBBR Mixing in Wastewater Treatment Applications

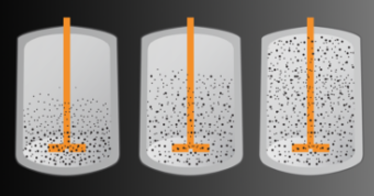

Today, moving bed biofilm reactor (MBBR) processes are widespread throughout the wastewater treatment industry. These processes rely on media with a high surface area to carry biofilm and achieve the same results as conventional bioreactors with reduced space requirements. MBBR mixing ensures that the media and influent are distributed uniformly throughout the reactor. Wastewater treatment facilities can adapt MBBRs to fulfill many process requirements. They can replace activated sludge processes and are also an attractive option for biological nitrogen removal. Many wastewater treatment facilities use a series of MBBRs with both anaerobic and aerobic steps. MBBR mixing must address several challenges and constraints to ensure process effectiveness and efficiency while also offering energy savings compared to dispersed air mixing. Key