Side entry mixers and top entry mixers play an important role in a diverse number of industries such as mining and natural resources, food processing, agricultural chemicals, oil and gas, wastewater treatment, food manufacturing, pulp and paper, brewing and distilling, paints and coatings, inks and dyes…

In every industry, engineers, consultants and operations managers need to carefully assess their unique requirements and environments, then look at the short- and long-term impact on everything from product quality and operating costs to the bottom line before committing to a mixer.

For many decision-makers, side entry mixers have been the most visible option thanks in part to side-entry and submersible suppliers’ ongoing marketing efforts. While Dynamix provides a full range of side-entry mixers, we often find ourselves showing clients how top-entry mixers can deliver significant energy savings and enhanced process control.

Dynamix is encouraging engineers, operations managers and engineering consultants to consider the true costs associated with side-entry and top-entry mixers respectively. Beyond the mixer’s impact on product quality, the capital outlay as well as operating costs must be considered, including energy consumption and maintenance and repair requirements (downtime included).

Let’s compare the capital and operating costs, which include energy use, maintenance and repair.

Side Entry Mixer:

Dynamix will recommend a side entry mixer when:

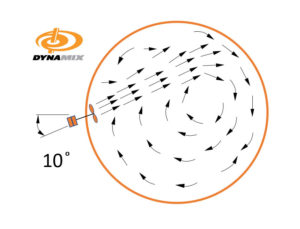

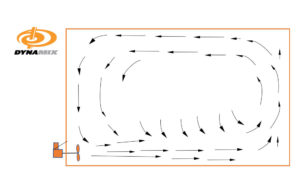

- the tank is much wider than the height (fluid level) and the aspect ratio is about 1: 1.75. This is typical in large holding tanks

- there isn’t enough ceiling clearance to put a mixer on top of the tank

Costs:

- Higher energy costs – side entry mixers require 3 to 5 times more mixing energy than most top-entry mixers

- Side-entry mixers push fluid along the walls of the tank which results in a less consistent mix and can lead to additional costs

- Higher maintenance costs because the tank must be completely drawn down for maintenance (note; this can also be avoided with our unique SMX side entry mixer which has a tank shut off. This allows the tank to be sealed at the mixer for maintenance).

- Mechanical seals are more critical and substantially more expensive to buy and maintain

Top Entry Mixer:

Dynamix will recommend a top entry mixer when:

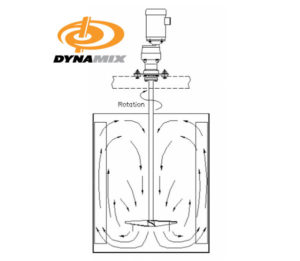

- the aspect ratio is about 1:1, but since top-entry mixers offer significant energy savings, several Dynamix designs make top-entry an option in much wider tanks / smaller aspect ratios.

Costs:

- Minimal maintenance costs

- Lower energy costs because top-entry mixers require 3 to 5 times less energy than most side-entry mixers

- Pure axial flow, top to bottom, results in a consistently high-quality mix

At Dynamix, we leverage our 45 years of industrial mixing expertise and experience, consult with our customers’ applications engineers and rely on our proprietary calculators to help our customers identify the best mixer configuration based on multiple factors.

Together, we determine the optimal aspect ratios based on their products’ viscosity and specific before recommending either top-entry or side-entry mixers.

To find out more about the pros and cons of side-entry and top-entry mixers, book your free 30-minute assessment with Dynamix today.