Mixing 101: 4 Factors for Configuring Your Fluid Mixer

Considering Mixer Configuration

If you’re in an industry that includes fluid mixing in its processes, you probably know that finding the right fluid mixer for your needs is critical to maintaining quality control, reducing costs, and optimizing efficiency.

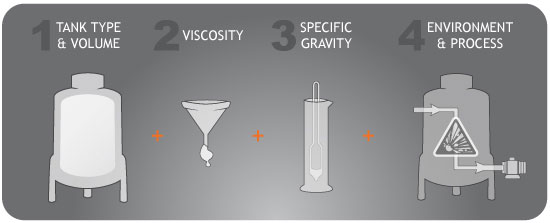

The key here is to engineer a fluid mixer that addresses the specific needs of your process. When configuring a mixer for your process, your mixing engineer should consider the following 4 factors:

Factor #1 – Tank Type & Volume

This determines the amount of fluid your tank can hold. This is important because it will determine the size and position of the fluid mixer and its mounting.

Factor #2 – Viscosity

This is “thickness” or “internal friction” of your fluid. It’s important because it will determine the impeller and horse power configurations.

Factor #3 – Specific Gravity

This is the density of the solid in comparison to water. It’s important because it will determine the type of pumping action that is required to adequately mix your fluid.

Factor #4 – Environment & Process

This is the setting where your mixing will take place. It’s important because it can determine the type of power source and finishes.

Engineering the Solution

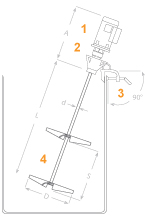

With this information in hand, your mixing engineer should configure a mixer with the following qualities:

With this information in hand, your mixing engineer should configure a mixer with the following qualities:

- Motor with suitable horse power and energy source

- Gear drive optimized for torque capacity

- Mounting fitted according to your tank needs

- Impeller sized to maximize efficiency

Summary

The fluid mixer you need depends on your process and the chemicals you use in that process. If you’re interested in learning more about mixing solutions for your process, post a comment or email us at info@dynamixinc.com.