Mixing 101: Flow Patterns & Impellers

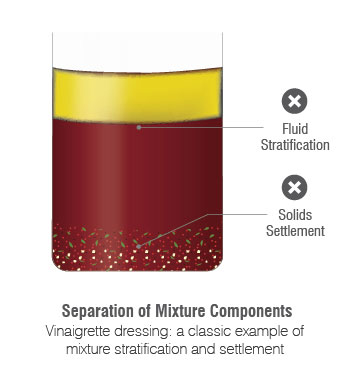

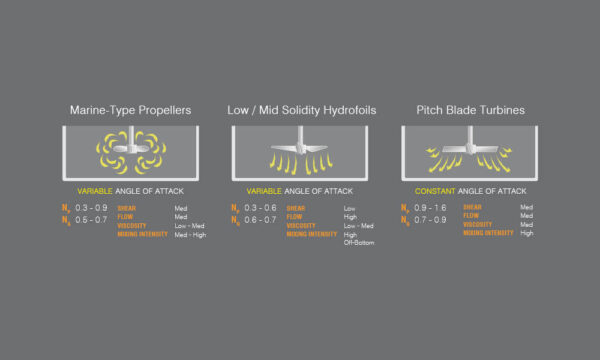

Mixing 101: Flow Patterns & Impellers Mixing Flow Patterns & Impeller Types In our article on 4 Impeller Types and Their Applications, we provided an overview on the most common types of impellers used in industrial mixing. Now we’ll go into more detail about each impeller type and their influences on the mixing process. Our focus on impellers is due to the fact that they are the part of the mixer that does the actual mixing: as they rotate they create fluid flow. These flow patterns are the primary considerations when designing a mixer because creating the right flow pattern is critical to achieving the desired result. The most common flow patterns in mixing are axial (down and up) and