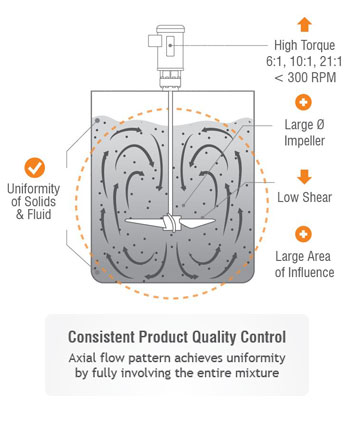

Keeping Your Solids in Suspension

Optimized Solids Suspension Applications Achieving a uniform dispersion of solids in a product is critical to your product’s quality. In processes that mix solids in fluid, particulates that cannot dissolve in liquids will either sink to the bottom of the tank and collect in the corners, or stick together and agglomerate. This compromises product uniformity (product quality), and in extreme cases, can cause a system to malfunction or fail. The main objectives of solid and liquid solutions are: Avoiding solids accumulation in a stirred tank Maximizing the contact area between solids in a liquid Ensuring the solid particles are uniformly distributed throughout the tank The goal is to bring the mixture into specification and keep it there. This means keeping