Mixing 101: Optimal Tank Design

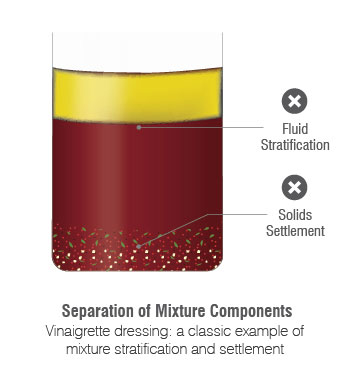

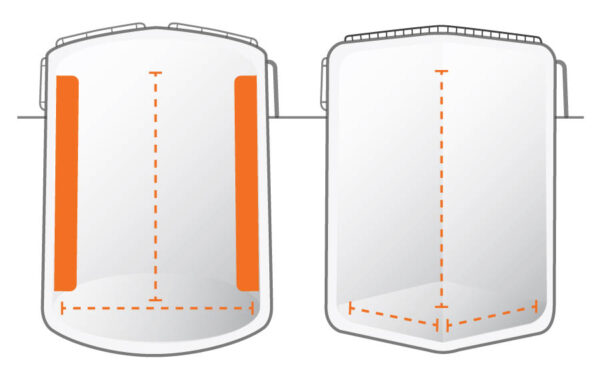

UNDERSTANDING HOW TANK DESIGN AFFECTS MIXING Apart from the actual mixer, the design of the mixing tank is the single most important factor in producing a successful result in any process. In order to allow optimal performance from a mixer’s impeller, it is essential to create an environment that supports both correct impeller positioning and appropriate liquid coverage of the impeller. Incorrect positioning negatively affects the performance of a mixer, the quality of a product, and may even be detrimental to the performance life of the mixer drive. When looking at tank designs, vertical cylindrical, and square or rectangular tanks are most common. In the process of selecting the optimal tank design for an application there are certain rules of