Mixing 101: Low rpm, High Torque Mixing

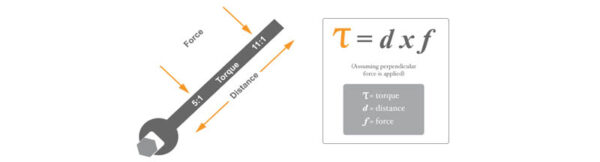

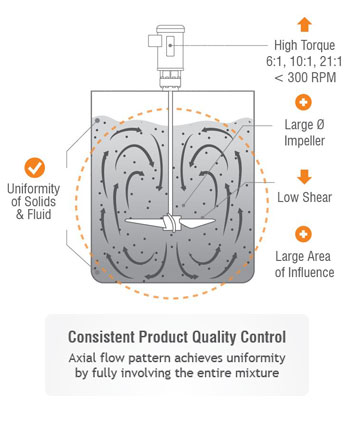

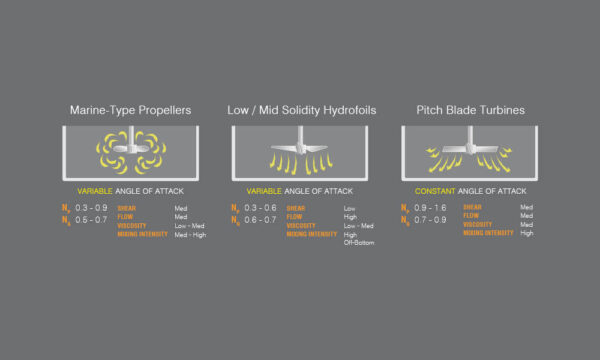

Mixing 101: Low rpm, High Torque Mixing In the process industry, there’s a strong focus on power as the defining characteristic in mixing. Many considerations are often left by the wayside when choosing a mixer. These factors can make or break the application. Relying solely on the G-Value or velocity gradient in mixer design leaves important information out of the equation. Focusing on the G-Value gives rise to the misconception that horsepower, rather than torque, is the critical factor determining mixing effectiveness. This method is effective for applications requiring high-sheer and turbulent flow, but this isn’t always the case. High-speed mixing introduces a host of additional considerations based on fluid viscosity, flow patterns, and shearing. Mixing Categories Different types of