Selecting Wastewater Mixers for Wastewater Treatment – Part 1

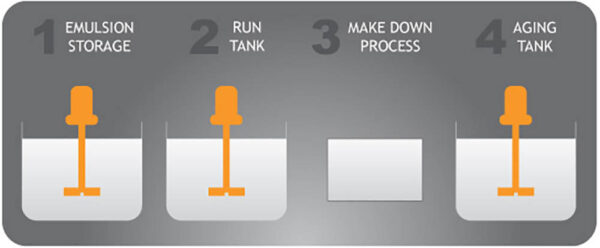

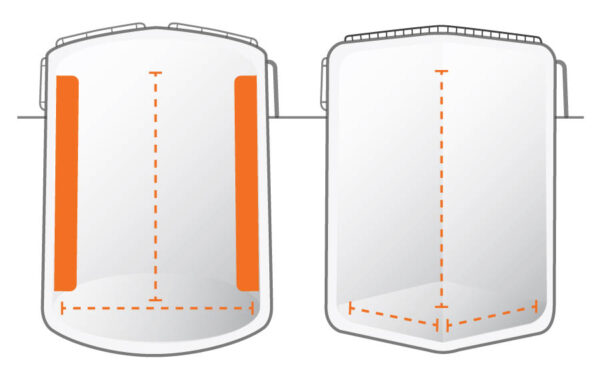

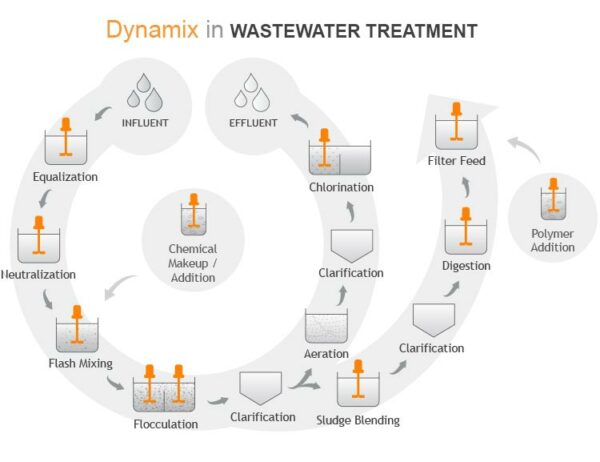

Selecting Wastewater Mixers for Wastewater Treatment – Part 1 Wastewater Mixers for Optimal Chemical Preparation Chemical preparation in wastewater and water treatment directly impacts many downstream processes. Let’s take a look at several common chemicals used and some key factors that influence their preparation and the selection of wastewater mixers. Lime Slurry Preparation When preparing lime slurries for controlling pH, uniformity is critical. Why? Because lime solids must reach/stay in suspension if they are to serve their purpose in downstream processes. For this reason, it’s essential that wastewater and water treatment facilities have lime slurry mixers that can efficiently and effectively make up/maintain uniform slurries. In order to successfully suspend/re-suspend solids, a mixer needs to create a flow pattern that involves the entire