Optimizing an Anoxic Mixer for Denitrification

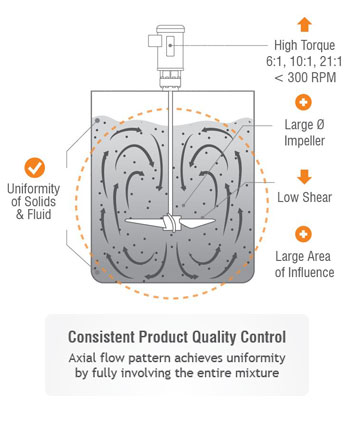

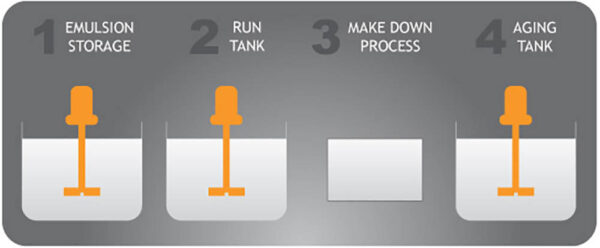

Optimizing an Anoxic Mixer for Denitrification in Water Treatment Simply adding bacteria to a wastewater plant does not guarantee that they will achieve the targeted task of denitrification. To encourage their growth, it is essential to first establish an anoxic environment, and then introduce an anoxic mixer that has been optimized specifically for the process. The Denitrification Process Denitrification in wastewater treatment is the conversion of nitrate (N03) to nitrogen gas (N2). It is a process that involves the reduction of nitrogen present in waste streams to an acceptable level so the treated water can be discharged into the environment via streams, ponds, lakes, etc. Lowering nitrate levels in a waste stream is achieved through creating an anoxic environment in which heterotrophic