COVID-19 Update

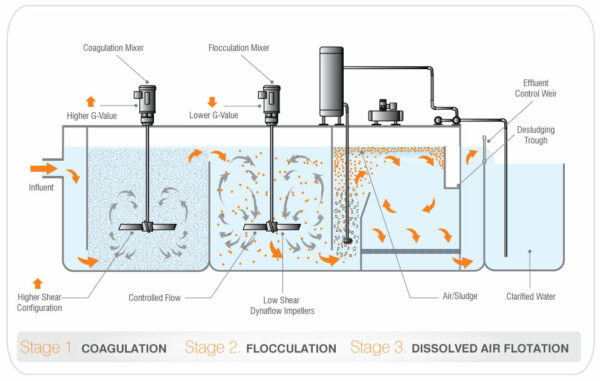

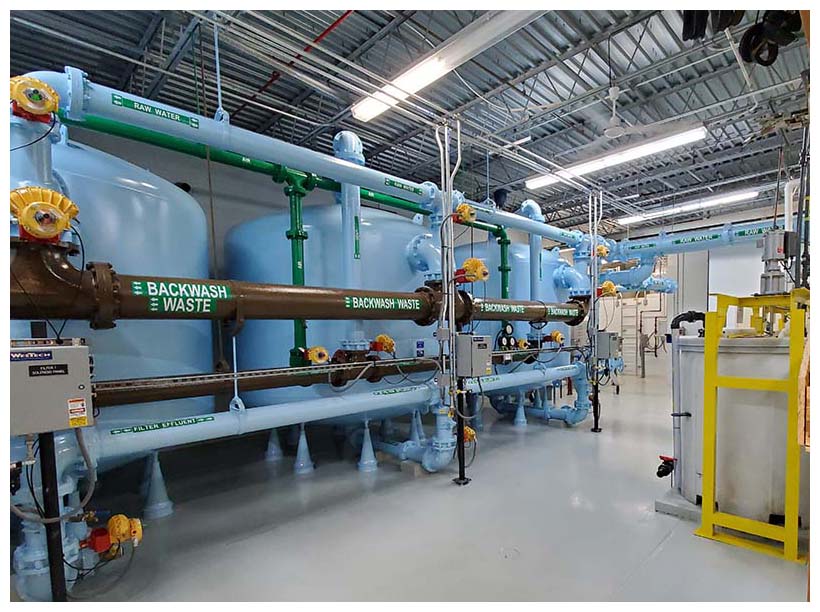

Dear Valued Customer: Dynamix Agitators Inc. (Dynamix) plays a key role in the supply chain to support vital industries such as water and wastewater, food and personal protection equipment (PPE), and parts. Defined as essential business, the Dynamix team will stay in operation to provide industrial wastewater equipment, hand sanitizer, and PPE manufacturing and equipment, engineering services, technical support, and the distribution of parts. Dynamix is a privately owned and operated company and have implemented extensive measures to ensure the health and safety of its employees, as outlined by the B.C. Health Authority. We also understand the importance of the environmental and health safety service Dynamix provides to our communities, country, and nations worldwide. Dynamix continues to work with its