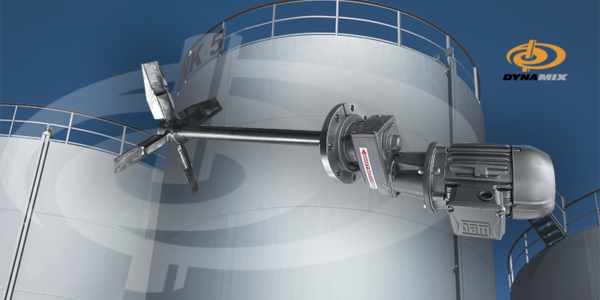

Maximizing Process Efficiency With Storage and Surge Tank Agitators

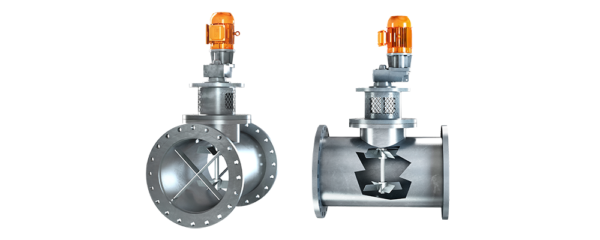

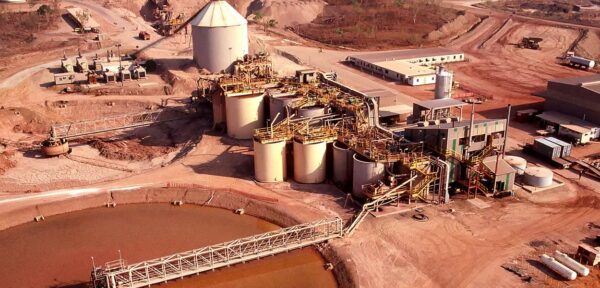

Hydrometallurgical processes, including gold leaching, require numerous storage and surge tanks. These tanks need agitation in order to provide a homogeneous feed to the next process step and prevent solids settling. Storage and surge tank agitators must meet these blending and suspension requirements while maintaining a low power requirement. At Dynamix, we provide innovative engineered solutions for storage and surge tank agitators with our GMX and NMX lines. The Problems Facing Slurry Storage and Surge Tanks The slurries handled in hydrometallurgical processes have varied parameters that make every application unique. Generally, the ore grind sizes are very fine, with a high solids concentration. Slurries will have increased viscosity and often show unexpected flow patterns. Anticipating these patterns is critical to